Metal parts are metal blocks, metal shafts, metal sheets, metal shell,etc. which are made of metal materials.

Materials of metal parts: steel and nonferrous metals (or non-ferrous metals). Metal has excellent properties that non-metallic materials such as plastics, wood, fiber and so on, which are irreplaceable in industrial products

1. Excellent conductivity, used to make conductive parts, such as motor rotor, electrical switch, socket.

2. Good thermal conductivity, can be used to make heat dissipation parts on machine equipment, such as heat sink, engine blade, etc.

3. Good plasticity, can be plastic deformation of metal materials, processing machine parts of various shapes.

4. Good weldability .

5. Metal materials have high mechanical properties, high strength and hardness.

6. The metal has high melting point and can be competent for high temperature working environment.

7. Metal parts can obtain good dimensional accuracy and surface quality, which are often used to make precision machine parts.

Metal parts are widely used in mechanical equipment, electronic appliances, shipbuilding, aviation and home furnishings. The metal parts we make for our customers are as follows: Shaft, gear, die casting, sintering, sheet metal

Machined parts

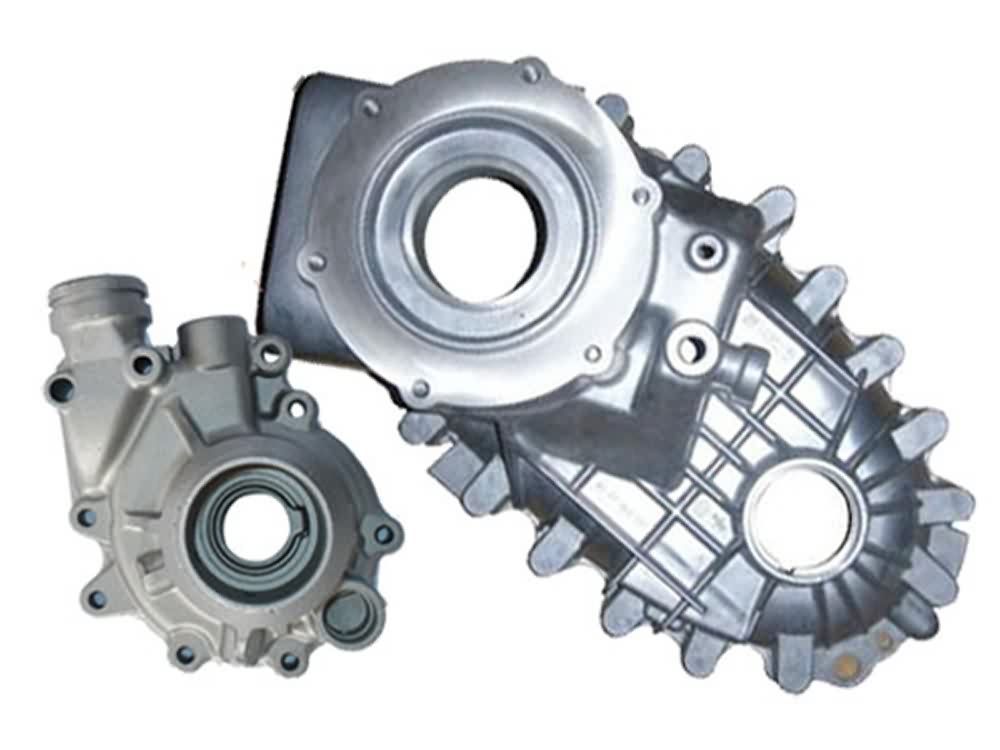

Die cast parts

Stamping parts

Stainless steel parts

Precision metal parts

Steel shaft

Worm gears

Aluminum die cast parts

Zinc alloy die cast parts

Sheet metal parts

Processing technology of metal parts Machining, stamping, precision casting, powder metallurgy, metal injection molding, laser machining, EDM, ultrasonic machining, electrochemical machining, particle beam machining and ultra-high speed machining. Similar to turning, milling, forging, casting, grinding, CNC machining, CNC CNC CNC center are machining conventional processing.

Surface treatment process

1. Anti corrosion and anti rust treatment: boiling black and boiling blue is also called phosphating treatment, so that metal parts have corrosion resistance and rust resistance.

2. Hardening treatment: the treatment method to increase the hardness of metal parts: surface carburization is adopted to increase the surface hardness of metal parts, and the surface color will turn black after carburizing; quenching treatment can increase the hardness;

3. vacuum heat treatment can improve the overall hardness.

Mestech provides customers with the design and processing of steel parts, aluminum alloy, copper alloy, zinc alloy and other metal parts. If you have metal products and parts to purchase , please contact us.