Metal part design

Short Description:

Metal parts design includes the definition of structural shape, dimension, surface accuracy and comprehensive mechanical properties, and finally come out drawings to final part manufacturing.

Metal parts are widely used in various industries. Metal parts design is the source of metal parts life. Mestech provides all kinds of precision metal parts processing, fixture processing and fixture processing for communication equipment, wind power equipment, medical equipment and electronic equipment .

The physical and chemical properties, size, shape, use environment and application of various metal parts are all inclusive and varied, and their processing technology is also very many.

To do a good job in the design of metal parts, there three important things we must make clear.

1.the use environment of the parts and the requirements for the parts

(1). Size requirements

(2). Hardness requirements

(3). Surface accuracy

(4). Anti corrosion requirements

(5). Strength requirements

(6). Rigidity requirements

(7). Electrical and thermal conductivity requirements

(8). Weight requirements

(9). Ductility requirements

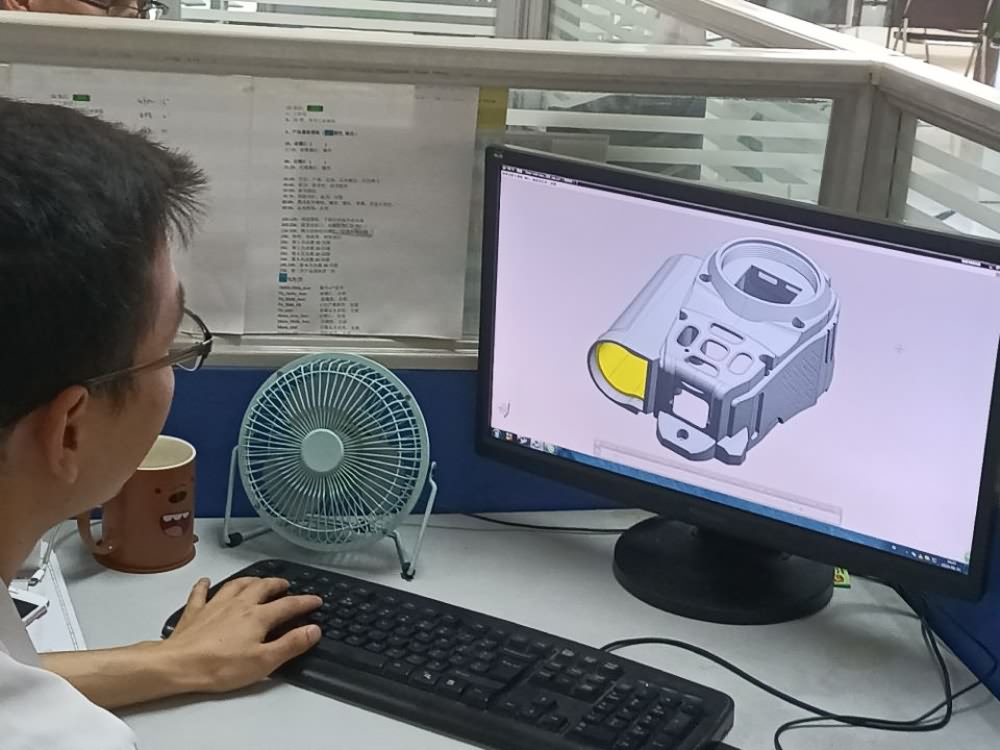

Engineer is designing

2. Choose the right materials correctly

The principles of selecting materials for designing metal parts are as follows:

(1) . meet the use performance: the material must be able to meet the design requirements of strength, toughness, hardness, conductivity and other indicators.

(2) Good processing performance: easy to process and stable production, to ensure a high pass rate, and to meet the design requirements of dimensional accuracy and performance requirements.

(3) Economy: it can realize large-scale production with low cost.

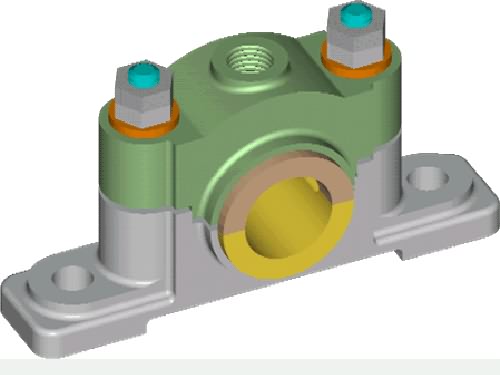

Plain bearing and bearing pedestal

Gear designed

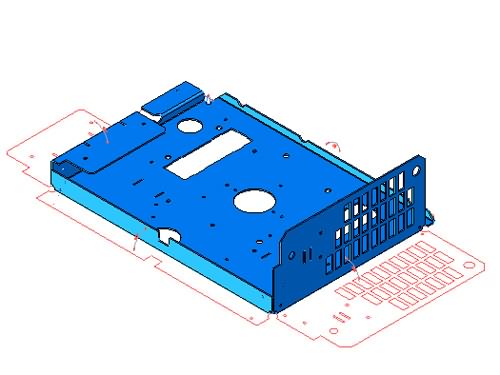

Stamping part

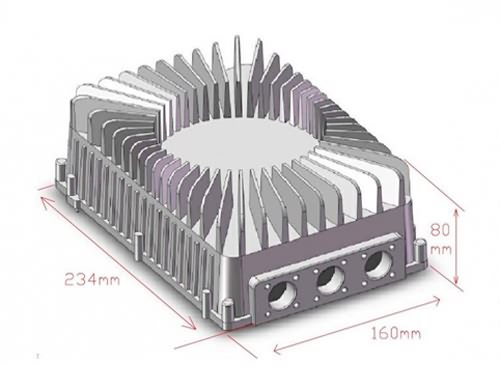

Aluminum housing

Considering the processing technology requirements of parts, that is, parts design should consider the relevant processing technology to ensure the required performance and accuracy, how to reduce the processing difficulty, cost and improve productivity.

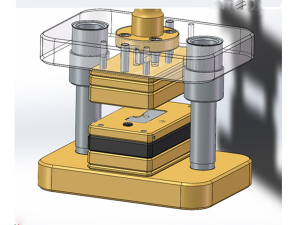

(1) Machining: for parts with strict mechanical properties (strength, hardness) and dimensional accuracy and stability, such as gears, crankshafts, bearings and other transmission parts for machine tools or construction machinery, steel or copper alloy is generally selected. The machining method is mechanical cutting.

(2) . stamping: for thin plate parts, such as containers, shells, lampshades or sheet parts, sheet metal or stamping is generally used. The precision of this processing technology is lower than that of cutting, so some parts with precision requirements need to be machined.

(3) Die casting: for some parts with complex shape, mainly non-ferrous metal parts, such as engine shell, radiator and lamp holder made of aluminum alloy, zinc alloy, magnesium alloy and copper alloy, die casting molding can greatly save the cutting amount and obtain high production rate. Suitable for mass production.

(4) Other processing technology: metal extrusion is suitable for mass production of metal profiles with constant cross section, and powder sintering is used for mass production of stainless steel parts.

Mestech provides customers with OEM design and processing of metal parts. If you have any need or need further information, please contact us.