Double injection molding

Short Description:

Double injection molding is a plastic moulding process in which two sets of moulds are simultaneously injected on the same injection machine to form one part of two different plastic materials.

Double injection molding (is also called double shot molding, two-color injection).

Double injection molding is a plastic moulding process in which two sets of moulds are simultaneously injected on the same injection machine to form one part of two different plastic materials. Sometimes the two materials are of different colors, sometimes two materials are of different hardness and softness, thus obtaining the required mechanical properties and aesthetics of the product.

The application of double-injection plastic mold and parts

The plastic parts produced though double-injection molding have been widely used in electronic products, electric tools, medical products, household appliances, toys and almost all other plastic fields. The production and molding of dual-color moulds, as well as the research and development of dual-color injection molding machines and raw materials for dual-color injection molding have also developed rapidly.

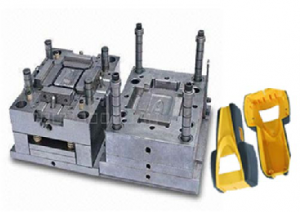

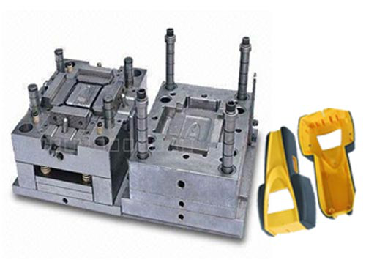

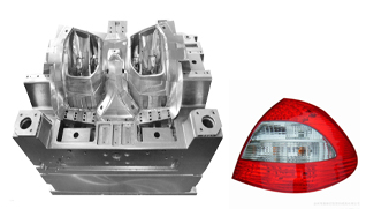

Show case of double-injection parts

Two different types of plastics are used, and the plastic products which can be clearly distinguished between the two types of plastics are called double-injection parts.

What is the advantage of double injection molding ?

Compared with traditional injection molding, dual-material co-injection moulding process has the following advantages:

1. The inner and outer layers of the parts adopt different materials with different characteristics, such as those with good strength in the inner layer and those with color or grain on the outer surface, so as to obtain comprehensive performance and appearance effect.

2. Material soft-hard coordination: The main body of part uses hard materials, the assembly matching surface using elastic soft resin (TPU, TPE) can play a very good sealing effect on the product, such as waterproof, dust-proof.

3. According to different usage characteristics, such as the surface layer of heavy parts uses soft plastic resin , the body or core of the part uses hard plastic resin or foamed plastic can reduce the weight.

4. Low-quality core materials can be used to reduce costs.

5. The core material of parts can use expensive and special surface properties, such as anti-electromagnetic interference, high conductivity and other materials to increase product performance.

5. The surface or core of parts can be made of expensive materials with special properties, such as anti-electromagnetic interference, high conductivity and other materials to increase product performance.

6. Proper mixing of cortical and core materials can reduce the residual stress, increase the mechanical strength or surface properties of the parts.

7. Compared with overmolding, it has great advantages in quality, cost and productivity.

The shortcoming of double injection molding

1. It is necessary to invest in the purchase of double-injection moulding machine.

2. The matching of double-injection moulds requires precision: the rear moulds have the same requirements. When the product has design changes, both moulds have to make the same changes to ensure the same. This adds workload to the maintenance of the die.

3. Double injection molding machine is that two pairs of moulds share the space and power of the same injection moulding machine, so large-scale products can not be injected.

The difference between double injection molding process and overmolding process

Double injection molding and overmolding are both secondary injection moulding, but they are quite different.

1. Overmolding process moulds, also known as secondary moulding, are carried out on ordinary injection moulding machines. The product is formed in two stages. After the product is removed from one set of moulds, it is put into another set of moulds for the second injection moulding. Therefore, ordinary injection moulding machine is used for overmolding process.

2. Double injection molding is that two kinds of plastic materials are injected on the same injection moulding machine, forming twice, but the product only comes out once. Generally, this kind of molding process is also called double material injection molding, which is usually completed by two sets of moulds and requires a special double-injection molding machine.

3. Double injection molding is a continuous mode of production. It has no operation of taking out and placing parts in the middle, saves time and error of re-placing parts, greatly reduces the rate of poor production, and greatly improves product quality and production efficiency compared with overmolding process.

4. Overmolding process is suitable for injection moulding of products with low quality requirements and small orders. Limited by the specifications of double-injection moulding machine, it is generally not suitable for injection moulding of larger parts.

5. The two front moulds of double-injection moulds must be identical, and the encapsulation moulds do not have this requirement. Therefore, the precision and cost of the double injection moulds are higher than that of the encapsulated injection moulds.

The tips of double-injection molding process:

1. In the process of double-injection injection molding, there are the four essential elements: double-injection molding machine, double-injection mold, appropriate plastic material and reasonable part design.

2. Material Selection of Soft and Hard Rubber double-injection Molding There must be a certain temperature difference between the melting point of two kinds of materials for two-color injection moulding. Generally, it is recommended that the melting point of the first injection material be higher than that of the second injection material, and that the melting point of the first injection material be higher than that of the second injection material.

3. Injection sequence of transparent and non-transparent materials: the first shot is made of non-transparent materials, and the second shot is made of transparent materials. For example, non-transparent materials are usually PC with high material temperature, and PMMA or PC is used for the second transparent material. PC needs to be protected by spraying UV. PMMA can choose UV or hardening. If there are characters on the surface, it must choose UV.

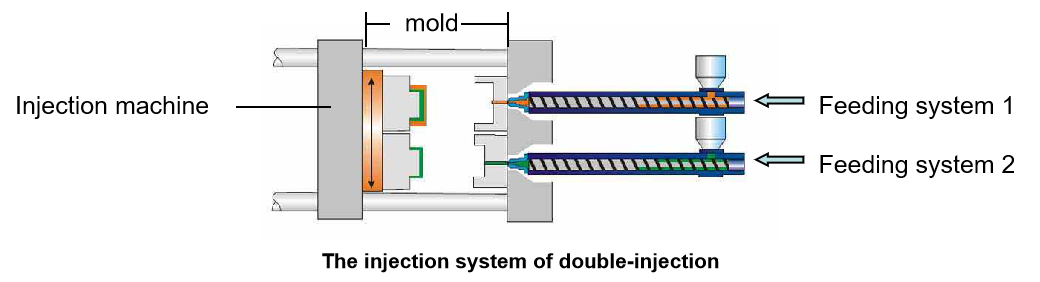

What is double-injection molding machine ?

The injection molding machine with two barrels and injection system and position conversion mechanism of mould is called double-injection molding machine, which is used for double-color injection moulding. Injection molding machines usually have two types: parallel injection moulding machine with injection screw and vertical injection molding machine with injection screw.

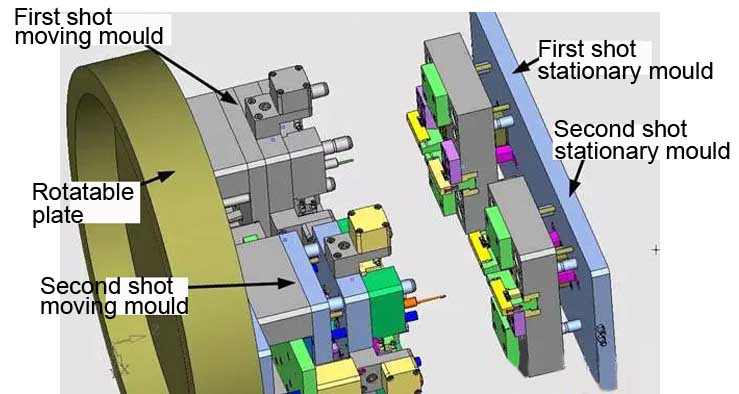

What is double-injection Mold ?

The mold which injects two kinds of plastics in sequence and produces two-color products is called two-color mould. Two-color injection moulds are usually two sets of moulds for one part, corresponding to the first and second shots respectively. The rear die (male die) of the two dies is the same, but the front die (female die) is different.

Double-injection moulds must be installed on double-injection moulding machine in order to produce normally.

Tips in the design of double-injection Molds

1. Mold core and cavity

The forming part of the double-injection mold is basically the same as that of the general injection mold. The difference is that the punch of the injection mold in two positions should be considered to be the same, and the concave mold should cooperate well with the two punches. Generally, this kind of plastic parts is smaller.

A DOUBLE-INJECTION MOLD

2. Ejection mechanism

Since the two-color plastic parts can only be demoulded after the second injection, the demoulding mechanism on the primary injection device will not work. For horizontal rotating injection machine, ejection mechanism of injection machine can be used for ejection ejection. For vertical rotating injection machine, ejection ejection mechanism of injection machine can not be used. Hydraulic ejection ejection ejection ejection ejection mechanism can be set on the rotary table.

3. Gating System

Because it is a double-injection molding, the gating system is divided into a single injection system and a secondary injection system, which are respectively from two injection moulding devices.

4, Consistency of mold bases Because the double-injection moulding method is special, it needs to cooperate and coordinate with each other, so the size and precision of the two pairs of die guide devices should be consistent. For horizontal rotating injection moulds, the closing height of the moulds should be the same, and the center of the two moulds should be on the same revolving radius, and the difference is 180. For a vertically rotating injection moulding machine, two pairs of moulds should be on the same axis.

Development of double-injection molding

From the characteristics and applications of multi-color injection moulding and dual-material co-injection moulding, it can be seen that there will be a trend to gradually replace the traditional injection moulding process in the future. Innovative injection moulding technology not only improves the precision of injection moulding process, but also opens up the field of injection moulding process. Innovative ejection equipment and processes are sufficient to meet the increasing demand for diversified, high-quality and high value-added products.

Mestech offer double injection moldinnng on automobile cases, handheld equipment shells, speakers housings, key buttons, handles and other two-color or two material products for years, please contact us if have demand .