In-Mold Decoration-IML

Short Description:

In-Mold Decoration (we called it IMD) is a popular surface decoration technology in the world. It is mainly used in the surface decoration and functional panel of household electrical appliances. It is often used in the panel and sign of mobile phone window lens and shell, washing machine control panel, refrigerator control panel, air conditioning control panel, automobile dashboard, rice cooker control panel and so on.

IMD is divided into IML (IMF belong to IML) and IMR, the biggest difference between the two processes is whether the product surface has a transparent protective film.

IMD includes IML,IMF,IMR

IML:IN MOLDING LABEL (printing materials and plastic parts)

IMF:IN MOLDING FILM(same as IML)

IMR: IN MOLD READ

IML (IN MOLD LABEL): The very remarkable process features of IML are: the surface is a layer of hardened transparent film, the middle is a printing pattern layer, the back is a plastic layer, because the ink clamped in the middle, can prevent the surface from scratching and abrasion, and can keep the color pattern bright and not fade for a long time. These characteristics make IML products widely used.

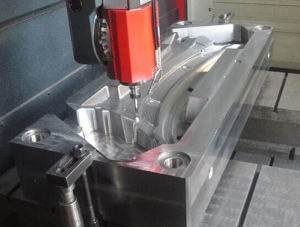

IML process: PET film cutting- plane printing - ink drying fixed - paste protective film - punching hole -Thermoforming - shearing peripheral shape - material injection molding.

The three tier structure of IML product:

1. Surface: Film (PET film, printing any pattern and color). Wood, cortex, bamboo, cloth, imitation wood, imitation leather, imitation cloth, imitation metal and so on;

2, the middle layer: ink (Ink), glue, etc.

3, bottom: plastic (ABS/PC/TPU/PP/PVC, etc.).

IMR (IN MOLD ROLLER): In this process, the pattern is printed on the film, and the film and the mold cavity are bonded by the film feeder for injection molding.

After injection, the ink layer with pattern is separated from the film, and the ink layer is left on the plastic part to get the plastic part with decorative pattern.

There is no transparent protective film on the final product surface, and the film is only produced. A carrier in the process. But the advantage of IMR lies in the high degree of automation in production and the low cost of mass production. IMR drawbacks: Printed pattern layer on the surface of the product, the thickness of only a few microns, the product will be easy to wear off the printed pattern layer after a period of time, but also easy to fade, resulting in a very unsightly surface. In addition, the new product development cycle is long, the development cost is high, the pattern color can not achieve small batch flexible change is also the IMR process can not overcome the weakness It is necessary to explain in concept: The key tips of IMR is the release layer .

IMR process: PET Film - release agent - printing ink - Printing Binder - internal plastic injection - ink and plastic then - after opening the mold, the film will automatically release from the ink. Besides the quality of printed sheets, dust has a great impact on their quality, and their production must be performed in a clean and dust-free environment

The fundamental difference between IML and IMR is that there are different lens surfaces, with PET or PC sheets on the IML surface and only ink on the IMR surface. IML wear resistance, scratch resistance and color pattern for a long time. IMR is convenient for mass production and low cost. IMR is not very wear-resistant, Nokia and Moto's phones are part of the IMR technology, slightly longer time will also cause scratches; the biggest drawback of IML is that it can not be implemented as a whole IML technology, only limited to a continuous area.

Features of IMD/IML products:

1, product design and color clarity, never fade, and three-dimensional sense;

2, the product has long service life, surface wear resistance and scratch resistance, and keeps the appearance clean and fresh.

3, printing accuracy of + 0.05mm, can print complex and multicolored patterns;

4, the pattern and color can be changed at any time during the production process without changing the mold.

5. The shape of IML products is not only plane shape, but also the shape of curved surface, curved surface, inclined surface and other special-shaped appearance effects.

6, the product does not contain any solvent based adhesive, which meets the environmental requirements.

7. The transmittance of windows is as high as 92%.

8. Functional keys have uniform bubbles and good handle. The keys are convex when they are injected into the mold. The life of the keys can reach more than one million times.

Plastic IMD case

Transparent panel with IML

IML case for communication device

Home appliance IMD key panel

IML application

At present, IML is widely used in many fields, such as windows, shells, lenses, automotive and household appliances control panel and decorative parts, which will be developed into anti-counterfeiting labels and automotive industry in the future. The product has good sunscreen performance, can be used for automobile signs, hardness up to 2H ~ 3H, can be used for mobile phone lenses, etc., button life can reach more than 1 million times, can be used for rice cookers and so on.

IMD/IML can produce part with beautiful appearance and wear resistant surface. But the cost is higher than the general surface parts. If your product needs such a product, please contact us.