China OEM Aluminium Pressure Die Casting Process Manufacturers - Die casting parts – Mestech

Short Description:

China OEM Aluminium Pressure Die Casting Process Manufacturers - Die casting parts – Mestech Detail:

Metal die casting part is a kind of pressure casting parts. It is a kind of pressure casting mechanical die-casting machine equipped with a casting die. It uses the metals such as copper, zinc, aluminum or aluminum alloy heated to liquid state to pour into the feeding port of the die-casting machine. After die-casting by the die-casting machine, it can cast the copper, zinc, aluminum parts or aluminum alloy parts with the limited shape and size of the die. Such parts are usually called die-casting parts. Die casting has different names in different places, such as die-casting parts, pressure casting, die-casting parts, die-casting aluminum, die-casting zinc, die-casting copper, copper die-casting, zinc die-casting, aluminum die-casting aluminum die-casting, aluminum die-casting alloy, aluminum alloy die-casting parts, etc.

Advantages of metal die casting parts:

(1) Good dimensional accuracy (depends on the casting material, but the first 2.5cm (0.004 inch for the first 1 inch) is usually 0.1mm, 0.02mm for every 1cm increase (0.002 inch for every 1 inch increase).

(2) Smooth cast surface (RA 1 – 2.5 microns or 0.04 – 0.10 microns). Thin walls can be cast compared to sand and permanent casting (about 0.75 mm or 0.030 in). Inserts can be cast in (e.g. threaded inserts, heating elements and high-strength bearing surfaces). Reduce or eliminate secondary machining operations. Fast production speed. The casting tensile strength is up to 415 MPa (60 Ksi).

Disadvantages of metal die casting

(1) The cost of capital is very high. Compared with other casting processes, the required casting equipment, molds and related parts are very expensive. Therefore, in order to make die casting an economic process, a large number of production is needed.

(2) For high flow metals only, the casting weight must be between 30 g (1 oz) and 10 kg (20 lb).

(3) In the standard die casting process, there will be a small amount of pores in the final casting. This can prevent heat treatment or welding, because heat will cause gas expansion in the pores, which will cause micro cracks and surface peeling in the parts, so the related disadvantage of die casting is that it is only applicable to parts with acceptable softness. Parts requiring hardening (by hardening or case hardening) and tempering are not cast in the mold.

Application of metal die casting parts:

Because of the advantages of metal die casting parts, it has been widely used, mainly in mass production of non-ferrous alloy castings. In the production of die-casting, aluminum alloy die-casting accounts for the largest proportion, accounting for 30% – 50%; zinc alloy die-casting is the second; copper alloy die-casting accounts for 1% – 2%. The most widely used die casting parts are automobile and tractor manufacturing, followed by instrument manufacturing and electronic instrument industry, and agricultural machinery, national defense industry, computer, medical equipment and other manufacturing industries. The parts produced by die casting method include engine cylinder block, cylinder cover, gearbox box, engine cover, shell and bracket of instrument and camera, pipe joint, gear, etc.

ypical metal die casting parts are used:

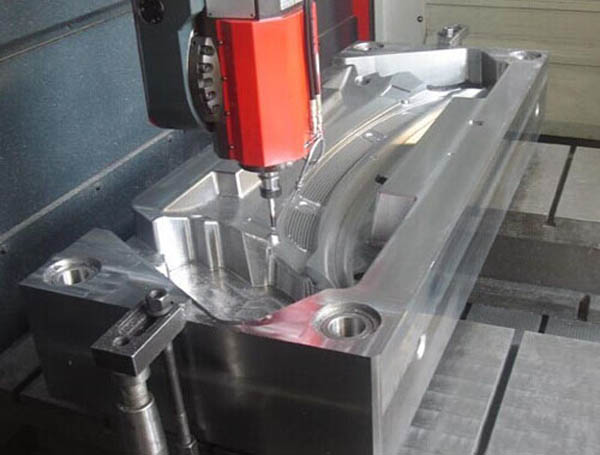

Product detail pictures:

Related Product Guide:

Cooperation

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for China OEM Aluminium Pressure Die Casting Process Manufacturers - Die casting parts – Mestech, The product will supply to all over the world, such as: Luxembourg, Munich, South Africa, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!