China OEM Die Casting Mold Products - Die casting process – Mestech

Short Description:

China OEM Die Casting Mold Products - Die casting process – Mestech Detail:

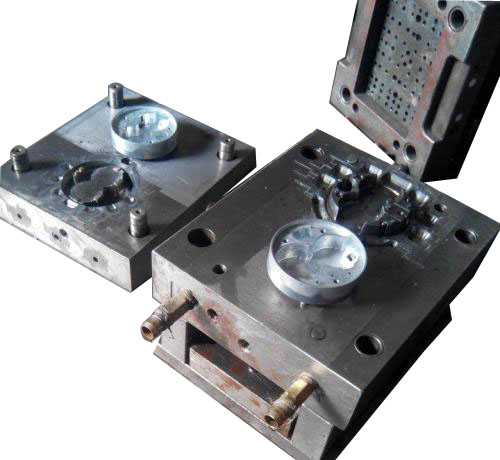

Metal die casting process is a process of unifying the pressure, speed and time by using the three elements of machine, mould and alloy. For metal hot working, the existence of pressure is the main characteristic of die casting process which is different from other casting methods. Pressure casting is a special casting method with less and no cutting, which has developed rapidly in modern metal processing technology. It is a process of filling the mold with molten metal under high pressure and high speed, and forming the casting by crystallization and solidification under high pressure. High pressure and high speed are the main characteristics of die casting. The commonly used pressure is tens of megapascals, filling speed (inner gate speed) is about 16-80m / s, and the filling time of metal liquid in mold cavity is very short, about 0.01-0.2s. Metal die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity and core is made using harden steel dies which have been machined into shape and work similarly to an injection mold during the process. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

5.Post Processing and Finishing for Die Casting Parts

We offer most post processing and finishing services for die cast parts from our select partners:

Services

CNC machining – vertical, horizontal, turning, 5-axis

Powder Coating

Liquid Coating

EMI – RFI Shielding

Plating – chrome, copper, zinc, nickel, tin, gold

Anodizing, Electrical Coating, Chromating/Non-chromating

Heat Treatment, Passivation, Tumbling

Graphics

In-house Artwork Process

Silk Screening

Pad Printing

Bead Blasting

Light Mechanical Assembly, including stud and helicoil inserts, O-ring, gasket

Laser Cutting and Engraving

Etching

Electrical Coating & Silk Screening

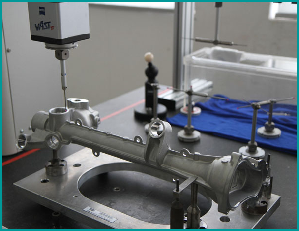

Die-casting part machining

Product detail pictures:

Related Product Guide:

Cooperation

The organization keeps on the procedure concept "scientific management, high quality and efficiency primacy, purchaser supreme for China OEM Die Casting Mold Products - Die casting process – Mestech, The product will supply to all over the world, such as: Russia, Iraq, Moscow, We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!