China OEM Double Shot Injection Molding Factory - Elastomer TPS wheel injection molding – Mestech

Short Description:

China OEM Double Shot Injection Molding Factory - Elastomer TPS wheel injection molding – Mestech Detail:

As a thermoplastic elastomer, TPS and PU wheels have excellent tensile strength, high surface friction coefficient, good low temperature performance, excellent electrical performance, no rolling noise and adsorption vibration, etc. They are mainly used for casters of hospital trolleys, baby carriages, shopping trolleys and airport trolleys.

Mestech can provide various sizes and types of TPS and PU materials for casters and single wheel moulding and injection moulding.

Tips of TPS wheel design

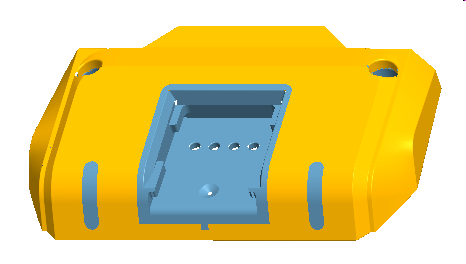

In order to increase the friction adhesion and better absorb vibration on the surface of the wheel, numerous holes and grooves with radial arrays centered on the hub axis are designed on the circumference of the plastic wheel. If the conventional die design is followed, the mold structure will be very complex or difficult to achieve, and the product will be difficult to withdraw. People have come up with a way: using elastic plastic TPS and PU as wheel coats, and putting them on the hub made of hard materials.

The elastomer TPS has the advantages of high friction coefficient, good wear resistance and good processing performance, good friction adhesion and vibration absorption, and good rigidity and strength depending on the hard central hub. At the same time, the elastic deformation characteristics of TPS and PU elastomers are used to forcibly pull out of the die cavity, thus avoid to make many complicated slider mechanism in the mold.

Our company is based in Guangdong, China. With good engineering experience and equipment, we provide themoplastic wheel design and production for your production, and ensure that the quality of products remains at a high level.

Product detail pictures:

Related Product Guide:

Cooperation

"Quality very first, Honesty as base, Sincere assistance and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for China OEM Double Shot Injection Molding Factory - Elastomer TPS wheel injection molding – Mestech, The product will supply to all over the world, such as: Iran, Kazakhstan, Bahamas, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.