China OEM Electrical Junction Box And Molding Factory - Nylon part injection molding – Mestech

Short Description:

China OEM Electrical Junction Box And Molding Factory - Nylon part injection molding – Mestech Detail:

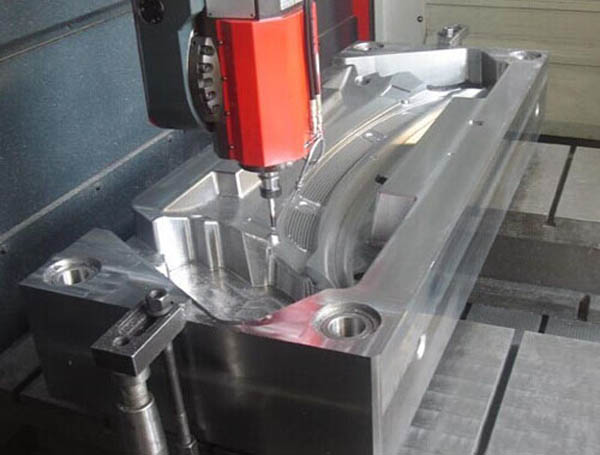

MESTECH has the injection molding machinery ranges in size from 90 to 1200 tons, allowing us to manufacture nylon plastic parts of many sizes and scales. We are happy to discuss nylon injection molding ideas and solution with each client to ensure the process and materials are an ideal fit for your project.

Nylon injection molding parts are used in many fields because of their excellent mechanical properties, such as gear pulleys, wheels, high voltage parts, cryogenic environment equipment, ultrasonic environment equipment, as well as replacing steel parts and aluminum parts for machinery and daily equipment.

What are nylon injection molded parts used for?

Nylon material is used in a large range of different industrial applications because of its impressive mechanical and electrical properties, excelling in toughness, wear resistance and chemical resistance. Nylon injection molding produces plastic parts that are used in countless industries and applications, such as:

Consumer apparel and footwear

Sports and recreation equipment

Industrial components

Medical products

Automotive products

Nylon is used for a variety of applications to include clothing, reinforcement in rubber material like car tires, for use as a rope or thread, and for a number of injection molded parts for vehicles and mechanical equipment. It is exceptionally strong, relatively resistant to abrasions and moisture absorptivity, long lasting, resistant to chemicals, elastic and easy to wash. Nylon is often used as a substitute for low strength metals. It is the plastic of choice for components in the engine compartment of vehicles because of its strength, temperature resilience, and chemical compatibility.

As nylon has great bending strength, it lends itself well for parts that will be intermittently loaded. Furthermore, with the high wear resistance and low coefficient of friction, nylon works well in applications such as slides, bearings and any device that is put through motion.

Product detail pictures:

Related Product Guide:

Cooperation

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for China OEM Electrical Junction Box And Molding Factory - Nylon part injection molding – Mestech, The product will supply to all over the world, such as: New York, Russia, Danish, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!