China OEM Injection Moulding And Blow Moulding Suppliers - How to choose your injection mold manufacturer – Mestech

Short Description:

China OEM Injection Moulding And Blow Moulding Suppliers - How to choose your injection mold manufacturer – Mestech Detail:

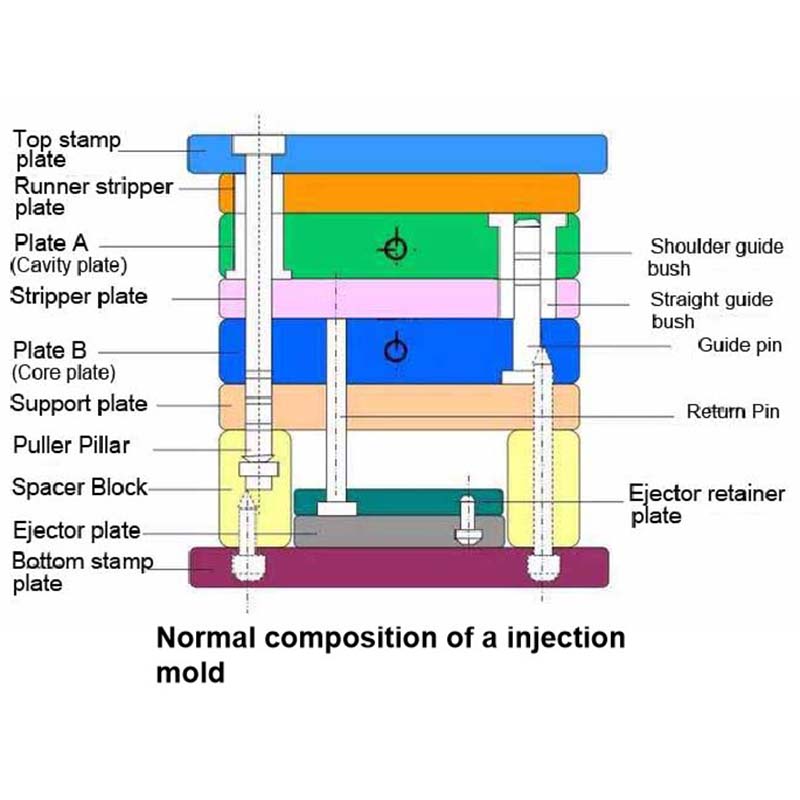

Injection mold is a kind of tool for forming plastic or hardware parts. The structure of injection mold is precise and complex, and must has high service life of several hundred thousands of injection cycles. It is a kind of high value equipment, and its quality plays a decisive role in the subsequent large volume injection production. So how to choose your injection mold manufacture is very important for you.

An injection mold is an actual machine without power, making it is a highly technical and time-consuming process. It is much more complicated than people imagine that how to get qualified mold in a short time at a reasonable price. Therefore, choosing a suitable mold company is very important for the success of your molds and products.

*Let’s share the detail knowledge on how to choose your injection mold manufacturer partners:

1. The manufacturer should have a professional engineering team

All moulds are manufactured in accordance with the engineer’s design drawings. The mold drawings are designed by engineers. Good mold always comes from perfect mold design. Mold design engineers must have competent knowledge and experience in mold related fields.

A failure of mold design often causes to much modification cost or even or mold failed. So a high quality design team is very important.

In addition to mold design engineers, but also must have professional process engineers, rely on them to reasonably formulate the processing process, to achieve high efficiency, low cost mold manufacturing.

2.What is the level of machinery and equipment used by the company for mold manufacturing?

The technical level and precision of machine tools directly determine the precision, time and cost of a mold. It is hard to imagine that a crude, dilapidated machine with low precision can produce high quality molds within a specified time. Blindly pursuing low price mold is bound to be inferior quality and long cycle.

A normal mold workshop is equipped with at least 4-5 CNC, EDM, WIRE-CUT machines. To avoid the influence of machine wear, the use time of the machines used for precision machining should not exceed 5-7 years.

So suggest you to make clear what the equipment level the company have before choose it as your partner.

3.What kind mold has the company can make, and how many molds they made in a month?

A company with experience of similar mold products can avoid some mistakes. Some special products, such as threads, gears, two-color injection molding, IMD and thin-walled parts of the mold, require special machinery and processing methods. So you can save time by knowing the type of mold and how long that the company has done in advance.

4.What is the cost of a mold?

The cost of a mold includes many more factors that aren’t always measurable in terms of the actual mold build. These include mold construction techniques involving the expertise and creativity of the mold builder that can result in vastly reduced cycle times, which can equate to a tremendous manufacturing cost savings over the life of the product.

Besides the steel, copper, hot runner and other physical objects used in the manufacture of molds, as well as the cost of machining and assembling test molds on machines, the below cost of molds must also be considered:

A) Engineering Costs

B) Rework Costs

C) Shipping Costs

D) Life of the Mold

5. Related or extended services

Usually you not only need the manufacturer to make the mold for you, but also you want them to do some product design, prototype verification, injection molding production and some necessary assembly and packaging extension services for you. Try to complete multiple processes in one roof to save time and cost..

6. Quality control and management

For manufacturing activities, whether it is mold processing or injection molding and assembly, a series of product standards and operation standards must be formulated and established to standardize and ensure the correct implementation of each link of production, and finally get the products with quality and performance specified by customers. Therefore, the manufacturer must have a perfect quality management system and process.

7.The manufacturing company must have an impeccable management.

You must check if the company is systematic when it comes to delivering the finished products on time and in a venue of your choice. It doesn’t matter how demanding your needs are. What matters is they can deliver it to you as promised.

items on choosing mold manufacturer

8.Consult before you make a conclusion.

You may have done tips one to four but it certainly will not hurt if you will consult with your family, friends, or an expert before making the final decision. If it will help, you may also browse the internet for reliable plastic molding companies.

Mestech company is engaged in mold design and manufacturing and injection molding production for more than 10 years, has a professional engineer team. The factory is equipped with a complete set of mold processing equipment CNC, electric spark, wire cutting and three-dimensional coordinate measuring instrument. It is equipped with 30 kinds of single-color and two-color injection molding machines ranging from 100 tons to 2000 tons. We provide local and overseas customers with export molds in accordance with Chinese standard, HASCO standard, DME standard or MISUMI standard, as well as one-stop service of injection molding, painting, silk screen, electroplating, hot stamping and laser engraving. We sincerely hope to be your supplier partner and provide you with high quality mold and injection products and services.

Product detail pictures:

Related Product Guide:

Cooperation

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for China OEM Injection Moulding And Blow Moulding Suppliers - How to choose your injection mold manufacturer – Mestech, The product will supply to all over the world, such as: Cairo, Islamabad, Georgia, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Thorough Info and parameters from the merchandise will probably be sent for you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.