China OEM Injection Moulding Machine Factories - Plastic housing for electrical inverter – Mestech

Short Description:

China OEM Injection Moulding Machine Factories - Plastic housing for electrical inverter – Mestech Detail:

The housings of most inverters are made of plastic, and inverter plastic housing are normally produced by injection molding.

A device that converts AC power with constant voltage and frequency to AC power with variable voltage or frequency is called ”inverter” or “frequency converter”.

Frequency converters are used in all electrical and mechanical equipments which are driven by motors to provide power suitable for the working frequency and voltage of motors to drive the operation of motors, and to control the machine and equipment to work according to the power and speed we need.

Frequency converters (inverters) are used in many fields:

1. Steel: rolling mill, rolling mill, fan, pump, crane, ladle car, converter tilting, etc.

2. Wire rolling: wire drawing machine, winding machine, blower, pump, hoisting machinery, fixed length shearing, automatic feeding.

3. Power: boiler, blower, feed pump, centrifugal mixer, conveyor belt, pump station, flywheel, etc.

4. Petroleum: oil pump, submersible electric pump, water injection pump, pumping unit, etc.

5. Paper industry: paper machine, pump, crusher, fan, mixer, blower, etc.

6. Transportation: ships, planes and cars.

7. Military: tanks, warships, fighter planes, radar.

The plastic housing of inverters

Frequency converters (inverters) are used in many fields:

1. Steel: rolling mill, rolling mill, fan, pump, crane, ladle car, converter tilting, etc.

2. Wire rolling: wire drawing machine, winding machine, blower, pump, hoisting machinery, fixed length shearing, automatic feeding.

3. Power: boiler, blower, feed pump, centrifugal mixer, conveyor belt, pump station, flywheel, etc.

4. Petroleum: oil pump, submersible electric pump, water injection pump, pumping unit, etc.

5. Paper industry: paper machine, pump, crusher, fan, mixer, blower, etc.

6. Transportation: ships, planes and cars.

7. Military: tanks, warships, fighter planes, radar.

The plastic housing of inverters

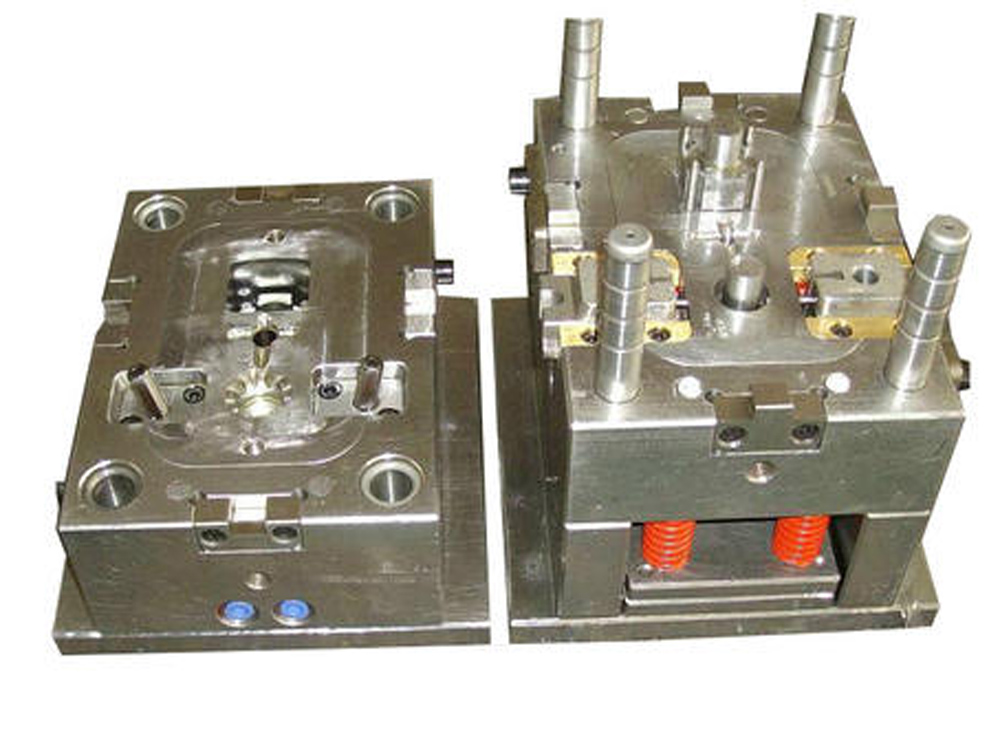

Injection molding technology of inverter housing

1 . requirements for converter plastic housing:

Generally, the frequency converter works in the medium and high voltage AC environment. In order to ensure safety, it is required to have good strength of the shell, bear the weight of internal electronic and electrical components for a long time, and have good flame retardancy. Especially for large machinery, ships and aircraft frequency converter, the requirements are very high.

Therefore, large wall thickness is adopted in shell structure. The shell screw column shall be put into the copper nut for injection molding together with the plastic, so that the shell, shell and internal electronic components are generally fixed with screws and copper nuts to ensure firmness.

2 . material selection

In order to prevent spark discharge and fire, flame retardant and anti-static PC / ABS is used in the shell.

3 . injection molding process

4 . injection molding process

When the shell is injection molded, it should be strictly controlled not to have sharp edge, flash and sharp angle, so as to prevent electric arc. Do not use recycled plastic to ensure the mechanical properties of the whole part。

Our company produces inverter injection mold and production for many customers. Please contact us if you need.

Product detail pictures:

Related Product Guide:

Cooperation

we could supply good quality goods, aggressive cost and very best purchaser assistance. Our destination is "You come here with difficulty and we supply you with a smile to take away" for China OEM Injection Moulding Machine Factories - Plastic housing for electrical inverter – Mestech, The product will supply to all over the world, such as: Costa rica, Portland, Ireland, All these products are manufactured in our factory located in China. So we can guarantee our quality seriously and availably. Within these four years we sell not only our products but also our service to clients throughout the world.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.