China OEM Making Plastic Parts Quotes - Where to use plastic parts – Mestech

Short Description:

China OEM Making Plastic Parts Quotes - Where to use plastic parts – Mestech Detail:

Plastic parts are made through mold molding with other processing methods, of which the size and function meet the designers’ requirements.

More than 80% of the plastic parts are molded by injection molding, which is the main way to obtain precision plastic parts.

Injection plastic parts and products have penetrated into all aspects of human activities, widely used in electronic communications, electrical appliances, electrical, instrumentation, security, automobile traffic, medical care, daily life appliances and other fields.

The main product categories are :

1. Communication electronic products and consumer electronics( plastic housing, enclosure, box, cover)

Mobile phones, headphones, televisions, video telephones, POS machines, doorbell.

2. Electrical appliances (plastic case, cover, container, base)

Coffee maker, juicer, fridge, air conditioner, fan washer and microwave oven.

3. Electrical equipment

Electric meter, electric box, electric cabinet, frequency converter, insulation cover and switch.

4. Instrument (plastic housing, cover)

Voltmeter, multimeter ,barometer, life detector

6. Traffic device and Vehicle appliances (lamp cover, enclosure)

Signal lamp, sign, alcohol tester,

7. Medical and health care

Operating lights, sphygmomanometer, syringe, dropper, medicine bottle, massager, hair removal device, fitness equipment

Different products require different sizes, shapes, performances, appearance and uses, so there are a variety of molds and injection molding processes used to make them.

Mestech has more than 10 years of injection mold manufacturing and injection production experience, we can provide you with customized injection molds and injection products and services according to your specification.

Such as:

1. ABS, PC.PMMA.PVC.PP.NYLON, TPU.TPE

2. injection molding for small parts, large parts, threads, gears, shells, two colors, and metal inserts molding.

3. Coating or surface decoration: screen printing, spray painting, electroplating, inner mold decoration, water transfer printing.

If you need plastic products for your products, or need to know more, please contact Mestech for quotation or further information.

8. Daily necessities

Plastic chairs, plastic toothbrushes, plastic basins, plastic buckets, plastic, plastic cups, glasses, toilet covers, pools, toys

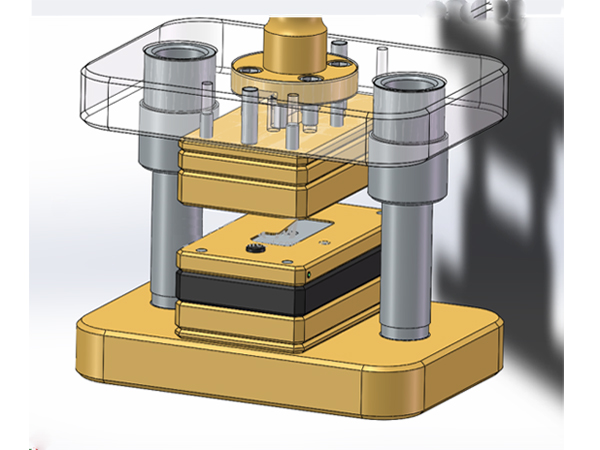

Product detail pictures:

Related Product Guide:

Cooperation

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for China OEM Making Plastic Parts Quotes - Where to use plastic parts – Mestech, The product will supply to all over the world, such as: Holland, Georgia, Zimbabwe, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.