China OEM Mini Plastic Injection Machine Factories - Plastic wheel and injection molding – Mestech

Short Description:

China OEM Mini Plastic Injection Machine Factories - Plastic wheel and injection molding – Mestech Detail:

Plastic wheels are widely used because of their easy manufacture, low cost, good shock, noise absorption and light weight. Injection molding is the main method of producing plastic wheel. The plastic wheel injection molding process is also widely used.

Generally wheel is are made of steel, aluminum alloy, plastic and wood. Compared with service life, production cost and user experience , wood has been eliminated because of poor durability, and poor resistance to water and fire. For aluminum, its load-bearing and wear resistance is not good.

Nowadays, mood wheel and aluminum wheel are gradually replaced by plastics wheel and steel. EXpcept large load-bearing equipment or precision machine parts such as cars, tanks and aircraft, Plastic wheel have been widely used in machinery, electronics, and People’s lives.

Plastic wheel is manufactured by injection molding. Plastic wheel of the same size only weigh one-seventh and one-sixth of the weight of steel wheel, one-third and one-half of the weight of aluminum wheel. Moreover, plastic will not rust. There are many types plastic resin with different characteristics , and parts that are easy to get different colors .

Most importantly, the good plasticity of plastics allows mass production at lower cost by mold injection molding. Injection molding can achieve good consistency in size and performance.

In addition, can take embedded metal parts or more than two kinds of plastic secondary molding, get comprehensive mechanical properties, appearance of a variety of products.

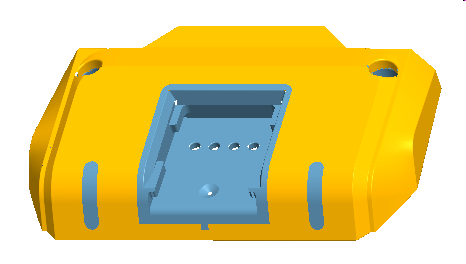

Tips of plastic wheel design

1) . shaft hole design

2) . thickness and hub design

3) . metal insert positioning

4) . draft angle and parting line position design

5) . stripe direction design of circular wheel surface

6) . material selection

Material selection of plastic wheels

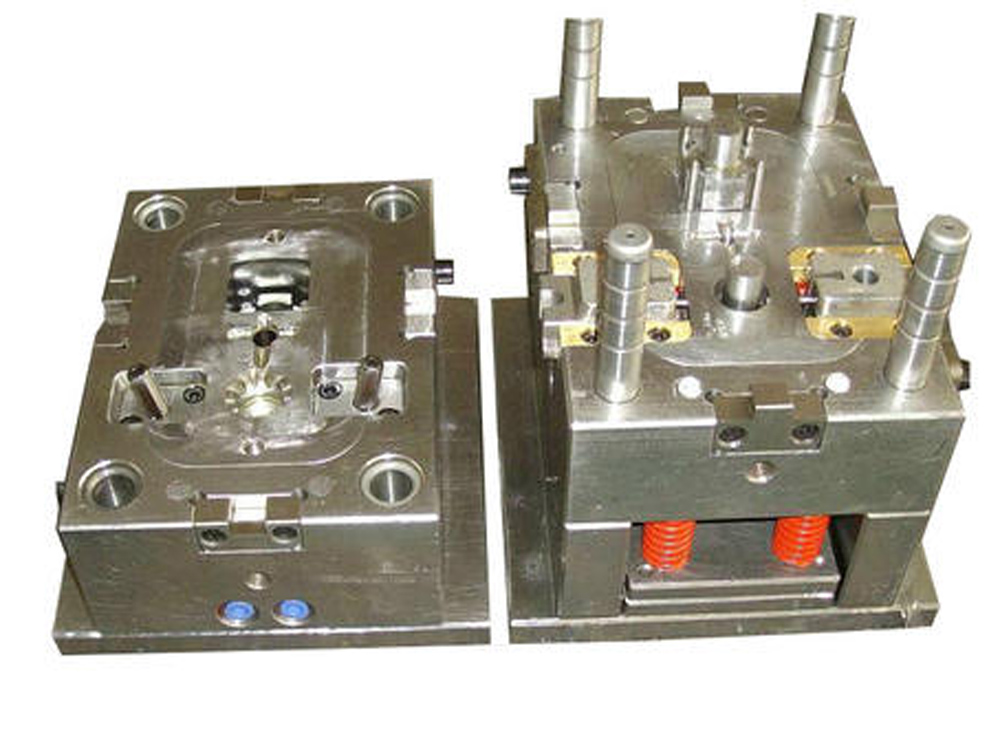

Several techniques to be considered in injection molding process of plastic wheel

point

Parting line and clamping position

Insertion position

Zoom out.

Nylon Injection

Two color injection

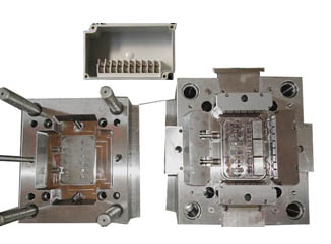

Mestech Industrial Limited helps customers design and manufacture injection moulds for plastic wheels, and selects the best materials for work requirements. We specialize in the production and technical services of molds and injection molding for the plastic wheels of various industrial carts, shopping carts, family carts, and toys. If you have any need in this area, please contact us.

Product detail pictures:

Related Product Guide:

Cooperation

Every single member from our higher effectiveness product sales staff values customers' requires and organization communication for China OEM Mini Plastic Injection Machine Factories - Plastic wheel and injection molding – Mestech, The product will supply to all over the world, such as: Birmingham, America, New Zealand, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!