China OEM Plastic Resin For Injection Molding Pricelist - Surface post processing of plastic parts – Mestech

Short Description:

China OEM Plastic Resin For Injection Molding Pricelist - Surface post processing of plastic parts – Mestech Detail:

Surface post processing of plastic parts are also called surface treatment and decoration of plastic parts Post processing of plastic parts is important processes to obtain the appearance of high quality products.

The exquisite and unique appearance of the product directly impacts the buyer with intuitive feeling and wins the interest of consumption. At the same time, it conveys clear product and manufacturer information to the customer, so as to win the market.

The surface treatment technology of plastic parts is to spray coating on the surface of injection moulded parts and print pattern characters, so as to protect the parts from external damage/get beautiful appearance and product brand information presented to customers.

1. surface spray paint

Plastic parts are sprayed with paint to protect the surface of the parts from direct contact with other objects, avoid scratches/scratches and oxidation, prolong the service life, and also beautify the appearance.

By means of air pressure, the spray gun disperses into uniform and fine droplets, which can be applied to the surface of the coating. (It can be divided into air spraying, airless spraying and electrostatic spraying, etc.).

Usually spraying gun is used to uniformly spray on the surface of the object, then the paint is dried and solidified to form a hard film. It has the functions of protection, beauty and marking. It is mainly used in automobiles, airplanes, plastics, wood, leather and so on.

Surface spray paint is widely used in electronics, electrical appliances, automobiles and other products and equipment.

A. Ordinary paint spraying.

Ordinary paint spraying is the most basic spraying technology. Its main function is to protect the surface of parts and prolong the service life and give the final color to the surface of parts. Ordinary paint can modulate a variety of colors to give the appearance of products. Ordinary paint can also modulate different gloss effects to a certain extent, but to obtain better gloss. Degree and handle, also need to add UV spray or Rubber spray on it.

B. UV spraying, Rubber spraying

UV Spray and rubber paint spray paint are all transparent paint.

UV spraying has good wear resistance, and can obtain better gloss and layer feeling than common paint spraying. It has three levels of spectrophotometry/neutrality/dumbness. UV spraying process depends on UV light curing .UV paint spray booth must be high class clean and dust-proof.

Rubber spraying is mainly used to create a soft touch layer of rubber or leather on the surface of parts.

UV paint and Rubber paint are transparent, and their affinity with plastic materials is not good enough, so most of them need to spray a layer of base paint as a medium before spraying them, usually representing the color of the product.

C. Conductive paint: Conductive paint is a special kind of spraying. It is mainly coated with a layer of paint containing conductive metal powder in the inner cavity of the part shell to form a shielding chamber to isolate the influence of electromagnetic waves between the internal and external environment of the product.

D. There are 3 important features to judge the quality of painting: 1. adhesive force 2. color value 3. gloss

The quality parameter for conductive paint is conductivity.

Plastic parts with surface paint sprayed:

2. screen printing and pattern decoration

A. Silkscreen printing

Silkscreen printing is the most commonly used printing method on the surface of plastic products. It is suitable for pattern printing on the bearing plane. When printing, ink is poured into one end of screen printing plate, and the scraper is used to exert certain pressure on the ink part of screen printing plate. At the same time, the ink moves uniformly towards the other end of screen printing plate. In the movement, the scraper squeezes the ink from the mesh hole of the graphic part to the substrate.

Silkscreen printing consists of five main elements: screen printing plate, scraper, ink, printing table and substrate. The screen printing tool is very simple, does not need machine equipment, and is mostly done by manual operation.

B.Pad printing

Pad printing is one of the special printing methods. It can print text, graphics and images on the surface of irregular shaped objects. Now it is becoming an important special printing. For example, the text and pattern on the surface of mobile phones are printed in this way, and the surface printing of many electronic products such as computer keyboards, instruments and meters is completed by transfer printing.

Because it has obvious advantages in printing on small area, concave and convex products, it makes up for the shortcomings of screen printing technology.

Pad printing requires a special transfer machine, which is mainly composed of plate device (including ink feeding device), ink scraper, offset head (usually silica gel material) and printing table.

Silkscreened printed and Pad printed parts:

3. Transfer printing

A. water transfer printing

Water transfer printing is a decorative printing for plastic products.

Water transfer printing is also called hydrographics or hydroGraphics, also known as immersion printing, water transfer printing, water transfer imaging, hydro dipping, watermarbling or cubic printing, is a method of applying printed designs to three-dimensional surfaces. The hydrographic process can be used on metal, plastic, glass, hard woods, and various other materials.

Water transfer printing technology is a kind of printing that uses water pressure to hydrolyze the transfer paper/plastic film with color patterns. With the improvement of product packaging and decoration requirements, the use of water transfer printing is more and more extensive. Its indirect printing principle and perfect printing effect solve many problems of product surface decoration, mainly used for transfer printing of various kinds of ceramics, glass flower paper and so on.

Water transfer technology has two very important characteristics: one is that it is not limited by the shape of the product, especially complex or large area, super-long, super-wide products can also be decorated;

The other is that it is a more environmentally friendly technology. Waste and waste water will not pollute the environment.

Advantage:

(1) Beauty: You can transfer any natural lines and photos, pictures and files on the product, so that the product has the desired landscape color. It has strong adhesion and overall aesthetics.

(2) Innovation: Water transfer printing technology can overcome the problems of complex shape and dead angle which can not be produced by traditional printing and thermal transfer, transfer printing, screen printing and surface painting.

(3) Extensiveness: It is suitable for surface printing of hardware, plastic, leather, glass, ceramics, wood and other products (cloth and paper are not applicable).

Because of its beauty, universality and innovation, it has the value added function to the processed products. It can be applied to home decoration, automobile, decoration and other fields, and has diversified patterns, and can be used with other effects.

(4) personalization: whatever you want, I shape myself, and any pattern will be designed with you.

(5) Efficiency: no plate making, direct drawing, immediate transfer printing (the whole process can be completed in 30 minutes, the most suitable proofing).

(6) Advantages: Rapid proofing, surface printing, personalized color painting and non-paper and cloth printing with many small patterns.

(7) the equipment is simple. It can be done on many surfaces that are not resistant to high temperature. There is no requirement for the shape of the transferred object.

Shortcomings:

Water transfer printing technology also has limitations.

(1) Transfer pictures and texts are easily deformed, which is related to the shape of the product and the nature of the water transfer film itself. At the same time, the price is higher, the more complicated the process, the higher the price.

(2) High cost of materials and labor costs.

B. Thermal transfer printing:

Thermal transfer printing is a technology that prints pattern on heat-resistant offset paper, and prints pattern of ink layer on finished material by heating and pressurizing. Even for multi-color patterns, because the transfer operation is only a process, customers can shorten the printing pattern operation and reduce the loss of materials (finished products) caused by printing errors. The printing of polychromatic patterns can be done at one time by using heat transfer printing film.

Advantage

(1) The printing effect is good, very beautiful.

(2) Artificial materials cost is low, production speed is fast, efficiency is high.

Disadvantages:

The product needs high temperature resistance (not suitable for plastic parts) and can only be transferred on regular surface.

4. Metal-plating

A. water electroplating

Water electroplating is done in water solution, so it is called “water electroplating”. More common are copper plating on the surface of plastic, nickel chromium, trivalent chromium, gun color, pearl nickel and so on.

In theory, all plastics can be electroplated by water, but at present only ABS, PC, ABS + PC are the most successful, but the adhesion of electroplated coating on other plastics is not satisfied. The process of water electroplating is simple and does not need to spray primer before and after plating. The coating has good adhesion, thick coating and low cost.

B. vacuum plating

Vacuum plating mainly includes vacuum evaporation plating, sputtering plating and ion plating. They are all used to deposit various metals on the surface of plastic parts by distillation or sputtering under vacuum conditions.

Non-metallic film, through this way can be very thin surface coating, and has the outstanding advantages of fast speed and good adhesion, but the price is also higher, generally used for comparison, functional coatings for high-end products.

Vacuum coating can be used in plastics such as ABS, PE, PP, PVC, PA, PC, PMMA, etc. Thin coatings can be obtained by vacuum plating.

Vacuum coating materials can be plated with a variety of metals, such as aluminum, silver, copper and gold, which have lower melting point than tungsten wire.

Comparison between water electroplating and vacuum plating:

(1) Vacuum plating is a process of coating in spraying line and vacuum furnace, while hydropower plating is a process in aqueous solution. Because it is spraying paint, vacuum plating is not suitable for complex shape products, while hydropower plating is not restricted by shape.

(2) Processing technology, such as vacuum coating of plastic glue, can be summarized simply: basic surface degreasing, dedusting, electrostatic precipitation, spraying UV primer, UV curing, vacuum coating, dedusting, spraying surface bottom (color concentrate can be added), curing, finished products; vacuum coating is limited by process, and it is not suitable to process products with too large area because of work. The art process is not well controlled, and the rate of bad is high.

Plastic electroplating (generally ABS, PC/ABS): chemical deoiling hydrophilic coarsening reduction preimpregnation palladium activation acceleration electroless nickel plating hydrochloric acid activation coke copper sulfuric acid activation semi-bright nickel nickel sealing chromium plating drying finished products;

(3) water and electricity plating can be completed in fully automated production.

(4) as far as appearance is concerned, the color brightness of vacuum aluminized film is brighter than that of water electroplating chromium.

(5) As far as performance is concerned, plastic vacuum coating is the outermost layer of paint, while water electroplating is usually metal chromium, so the hardness of metal is higher than that of resin;

As for corrosion resistance, paint coating is usually used. Cover layer is better than metal layer, but there is little difference between them in high-end product requirements; in weathering, hydropower plating is better than vacuum plating, so it usually needs long-term outdoor use with weather resistance.

In the automotive industry, there are also strict requirements for resistance to high bottom temperature, humidity and heat, solvent wiping and so on.

6) Vacuum plating is mainly used in the electronic communication industry, such as mobile phone shell, automotive applications, such as reflective cups of automotive lamps; water plating is mainly used for decorative chromium, such as automotive door trim. Door knobs and so on.

(7) In terms of product appearance color diversity, vacuum plating is richer than water plating. Vacuum plating can be made into gold and other color surfaces.

(8) as far as processing cost is concerned, the current vacuum plating cost is higher than that of water plating.

(9) Vacuum plating is a green environmental protection process with rapid technological development, while water electroplating is a traditional process with high pollution, and the industry is limited by the influence of national policies.

(10). Here is a brief introduction of the spraying process (silver mirror reaction) which has just emerged. The process is plastic degreasing and deelectrostatic special primer baking nano-spraying pure water baking.

This technology can also make mirror effect on plastic surface. It is also an environmentally friendly process.

The former and the latter processes are the same as vacuum plating, but only the middle plating.

Aluminum is replaced by silver-sprayed mirror, but the current technical performance of this process can not be compared with water plating and vacuum plating. It can only be applied to handicraft products which do not require high appearance and performance.

5. Hot stamping

Hot stamping is also called bronzing or gold stamping.

A printing and decoration process. The metal plate is heated, gold foil is printed, and the gold characters or patterns are printed on the printed matter. With the rapid development of hot stamping gold foil and packaging industry, the application of electrified aluminium stamping is more and more extensive.

In the printing process of plastic products, hot stamping and silk printing are relatively easy to operate and widely used printing processes. They have the characteristics of low cost, easy processing, not easy to fall off, beautiful and generous, and rich performance. They can print various company names, LOGO, propaganda, logos, codes and so on.

Principles and characteristics of gold stamping technology:

The hot stamping process uses the principle of hot pressing transfer to transfer the aluminium layer in electrolytic aluminium to the surface of the substrate to form a special metal effect. Because the main material used in the hot stamping is electrolytic aluminium foil, the hot stamping process is also called electrolytic aluminium stamping. Electrolytic aluminium foil is usually composed of multi-layer materials, the base material is usually P E, followed by separation coating, color coating, metal coating (aluminium plating) and glue coating.

(1) Surface decoration can increase the added value of products. Combined with other processing methods such as bronzing and pressing bump, it can show the strong decorative effect of the product.

(2) To give the products higher anti-counterfeiting performance, such as holographic positioning, hot stamping, trademark identification, etc. After the product is bronzing, the patterns are clear, beautiful, colorful, wearable and weather resistant. At present, the application of bronzing technology on printed tobacco labels accounts for more than 85%. In graphic design, bronzing can play a key role in highlighting the design theme, especially for the decorative use of trademarks and registered names.

6.Laser engraving

Laser engraving is also called radium carving or laser marking. It is a surface treatment technology based on optical principle. Laser engraving is also a surface treatment process, similar to screen printing, is printed on products or patterns, and the process is different, the price is different. The principle of laser processing.

(1) The high intensity focused laser beam emitted by the laser is used to oxidize the material and process it.

(2) The effect of marking is to expose deep substances through evaporation of surface substances, or to cause traces of chemical and physical changes of surface substances by light energy, or to burn some substances by light energy, and to “engrave” traces, or to burn some substances by light energy, to show the required etching graphics and words

(3). Case

For example, I want to make a keyboard, which has words on it, such as blue, green, red keys, and then spray a whole layer. White, this is a whole white keyboard, and all the blue and green are and gray, the key body is white, laser engraving, first spray oil, blue, green, red, gray, each spray the corresponding color, pay attention not to spray on other keys, so that it looks like there are blue keys, green keys and other wrapped under it. At this time, laser carving can be carried out, using laser technology and ID keyboard maps made of film, carved out the top white oil, such as the processing letter “A”, carved out the white strokes, then the next or blue or green will be exposed, thus forming a variety of color letter keys.

At the same time, if you want to be transparent, use PC or PMMA, spray a layer of oil, carve out the font part, then the light below will come out, but at this time to consider the adhesion of various oils, do not spray on the scratch off

Mestech not only provides customers with mold making and parts injection production, but also provides customers with one-stop surface treatment services such as painting, electroplating, etc. If your product has such a demand, please contact us.

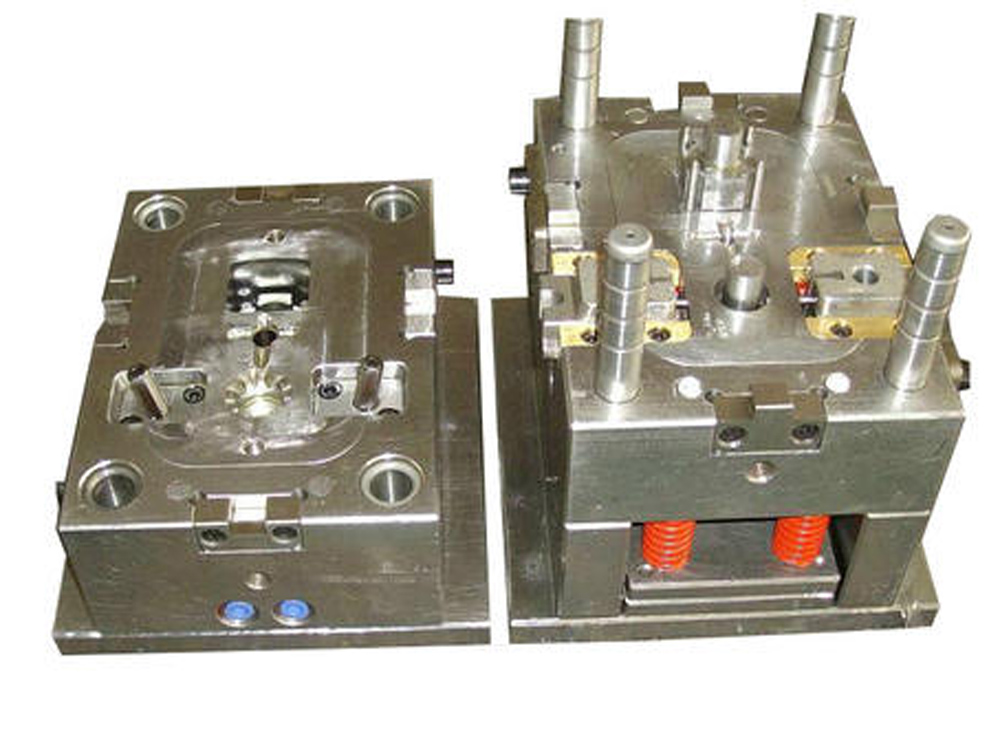

Product detail pictures:

Related Product Guide:

Cooperation

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of China OEM Plastic Resin For Injection Molding Pricelist - Surface post processing of plastic parts – Mestech, The product will supply to all over the world, such as: Las Vegas, India, Israel, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.