China OEM Post Processing Of Plastic Parts Factories - Elastomer TPS wheel injection molding – Mestech

Short Description:

China OEM Post Processing Of Plastic Parts Factories - Elastomer TPS wheel injection molding – Mestech Detail:

As a thermoplastic elastomer, TPS and PU wheels have excellent tensile strength, high surface friction coefficient, good low temperature performance, excellent electrical performance, no rolling noise and adsorption vibration, etc. They are mainly used for casters of hospital trolleys, baby carriages, shopping trolleys and airport trolleys.

Mestech can provide various sizes and types of TPS and PU materials for casters and single wheel moulding and injection moulding.

Tips of TPS wheel design

In order to increase the friction adhesion and better absorb vibration on the surface of the wheel, numerous holes and grooves with radial arrays centered on the hub axis are designed on the circumference of the plastic wheel. If the conventional die design is followed, the mold structure will be very complex or difficult to achieve, and the product will be difficult to withdraw. People have come up with a way: using elastic plastic TPS and PU as wheel coats, and putting them on the hub made of hard materials.

The elastomer TPS has the advantages of high friction coefficient, good wear resistance and good processing performance, good friction adhesion and vibration absorption, and good rigidity and strength depending on the hard central hub. At the same time, the elastic deformation characteristics of TPS and PU elastomers are used to forcibly pull out of the die cavity, thus avoid to make many complicated slider mechanism in the mold.

Our company is based in Guangdong, China. With good engineering experience and equipment, we provide themoplastic wheel design and production for your production, and ensure that the quality of products remains at a high level.

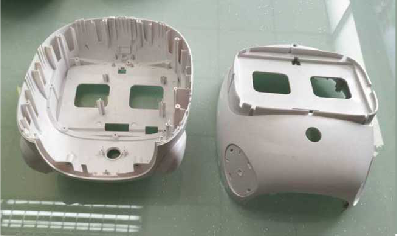

Product detail pictures:

Related Product Guide:

Cooperation

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for China OEM Post Processing Of Plastic Parts Factories - Elastomer TPS wheel injection molding – Mestech, The product will supply to all over the world, such as: Norway, Naples, Mali, Our experience makes us important in our customer eyes. Our quality speaks itself the properties like it do not tangle, shed or breakdown, so that are our customers will always be confident while placing an order.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.