China OEM Post Processing Of Surface Treatment Factories - Automobile plastic parts – Mestech

Short Description:

China OEM Post Processing Of Surface Treatment Factories - Automobile plastic parts – Mestech Detail:

The automobile industry is a large family of machine manufacturing, involving almost all fields of machinery and electronics. Plastic parts account for 30% ~ 40% of the parts in the automobile. Therefore, plastic auto parts occupy a large proportion in the automobile industry.

Mestech is a professional mold manufacturer on plastic injection molded automotive Parts. We devote in the molds making and injection of the automotive parts of interior and exterior trim components, electronic subassemblies, and under-hood etc.

We make injection molds and produce various aumobile components below:

Automobile bumper

Dashboard

Automobile lighting

Defog grille

Glove box

Air conditioning outlet

Instrument Panel Components

Acrylic Lens

Interior Bezels

Shifter Knobs & Assemblies

Keyless Entry Housings

Back Lighting Controls & Buttons

Pads & Cushions

Insert Molded Spacer Blocks

Door Handle Components

Sunroof Components & Assemblies

DVD Housings

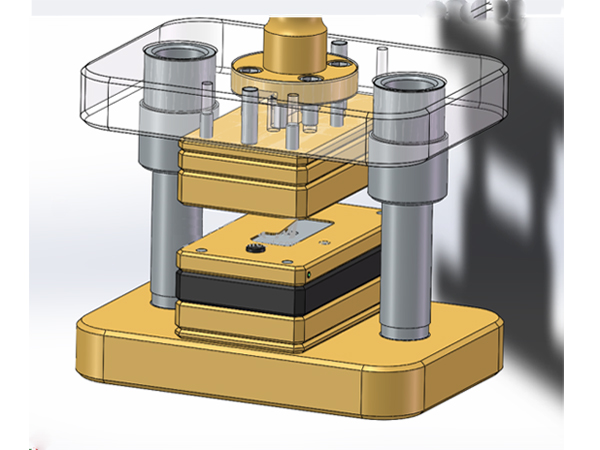

The characteristics of auto part molds:

1 .Large size: auto part like car bumpers, fenders, hoods, grilles, doors, backseats, front covers are in larges size, so the injection molds are need to be made in large size as well. This would require the injection mold makers to invest on large size machines.

2 .Complex surface: part with complex surface need to be machined by high speed and high precision CNC.

3 .High quality: There are many parts on a car, which are matched precisely. It requires not only accurate size, but also beautiful appearance and reliability. Especially lamps, instrument panel and other parts.

Mold flow analysis is highly recommended in design stage. For a long melt flow auto parts like car bumpers and grilles, application of mold flow analysis can provide the optimum gating solution and minimize injection molding cycle, multiple hot nozzles are employed frequently.

Mould steel:S136, NAK80, 738H, SKD61, P20, 718, 718H, 2738, 738, etc.

Plastic Material: ABS, PP, POM, PS, PVC, HDPE, HIPS, etc.

Mould base: LKM

Hot runner: YUDO, Mold Masters etc as specified.

Standard parts: DME, HASCO, etc.

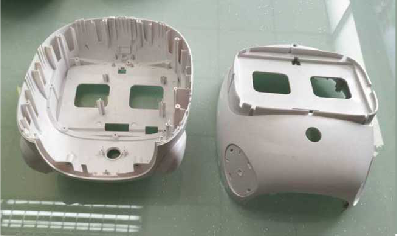

Plastic injection molds for automobile

Tips of producing injection molds for plastic automotive components

1 .Automotive parts generally not only requires dimensions accuracy but high quality surface quality.

2 .In order to obtain high surface quality, parts are not allowed to have fusion lines/air lines and shrinkage marks on the surface. Therefore, the hot runner feeding system should be adopted to avoid the sharp angle affecting the flow in the mold design.

We uses good quality of steel S136,NAK80 and P20 for making cavities, cores and inserts of molds. We produce the molds of standards of DME,HASCO,MISUMI according to customer’s specification.

Mestech manufactures products from engineered resins (polycarbonates, GF nylons, PET, PP, etc.) to cosmetic parts such as acrylic instrument lens and bezels. Secondary operations such as sonic welding and pad printing are used as well.

Product detail pictures:

Related Product Guide:

Cooperation

To continuously increase the administration process by virtue of the rule of "sincerely, good religion and excellent are the base of company development", we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for China OEM Post Processing Of Surface Treatment Factories - Automobile plastic parts – Mestech, The product will supply to all over the world, such as: Poland, Bangladesh, Ethiopia, To meet the requirements of specific customers for each bit more perfect service and stable quality merchandise. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.