China OEM Semi Automatic Plastic Injection Moulding Machine Suppliers - Spraying paint for plastic products – Mestech

Short Description:

China OEM Semi Automatic Plastic Injection Moulding Machine Suppliers - Spraying paint for plastic products – Mestech Detail:

Paint spraying for plastic parts is one of the most commonly used processes.

Surface spray paint is widely used in electronics, electrical appliances, automobiles and other products and equipment.

There are three purposes for plastic parts are sprayed with paint:

(1) to protect the surface of the parts from direct contact with other objects, avoid scratches/scratches and oxidation, prolong the service life,

(2) to conceal the defect in surfaces, beautify the appearance.

(3) give the final color to the product appearance.

According to the characteristics of paint and the purpose and function of product spraying, there are main four types of spraying processes below.

1. Ordinary paint spray

Ordinary paint spraying is the most basic spraying technology. Its main function is to protect the surface of parts and prolong the service life and give the final color to the surface of parts. Ordinary paint can modulate a variety of colors to give the appearance of products.

Ordinary paint can also modulate different gloss effects to a certain extent, but to obtain better gloss. Degree and handle, also need toadd UV spray or Rubber spray on it.

2.UV spraying

UV spraying has good wear resistance, and can obtain better gloss and layer feeling than common paint spraying. It has three levels of spectrophotometry / neutrality/dumbness. UV spraying process depends on UV light curing .UV paint spray booth must be high class clean and dust-proof.

UV spraying is sometimes used as the top spraying coating on the vacuum coating or water transfer layer, which plays a protective and curing role.

3.Rubber spraying

Rubber spraying is mainly used to create a soft touch layer of rubber or leather on the surface of parts.

UV paint and Rubber paint are transparent, and their affinity with plastic materials is not good enough, so most of them need to spray a layer of base paint as a medium before spraying them, usually representing the color of the product.

4. Conductive paint

Conductive paint is a special kind of spraying. It is mainly coated with a layer of paint containing conductive metal powder in the inner cavity of the part shell to form a shielding chamber to isolate the influence of electromagnetic waves between the internal and external environment of the product.

Conductive paint is generally used in communication and communication products, which rely on high-frequency electromagnetic wave products are extremely sensitive to external electromagnetic signals. Therefore, it is necessary to spray metal paint in the shell to shield electromagnetic interference.

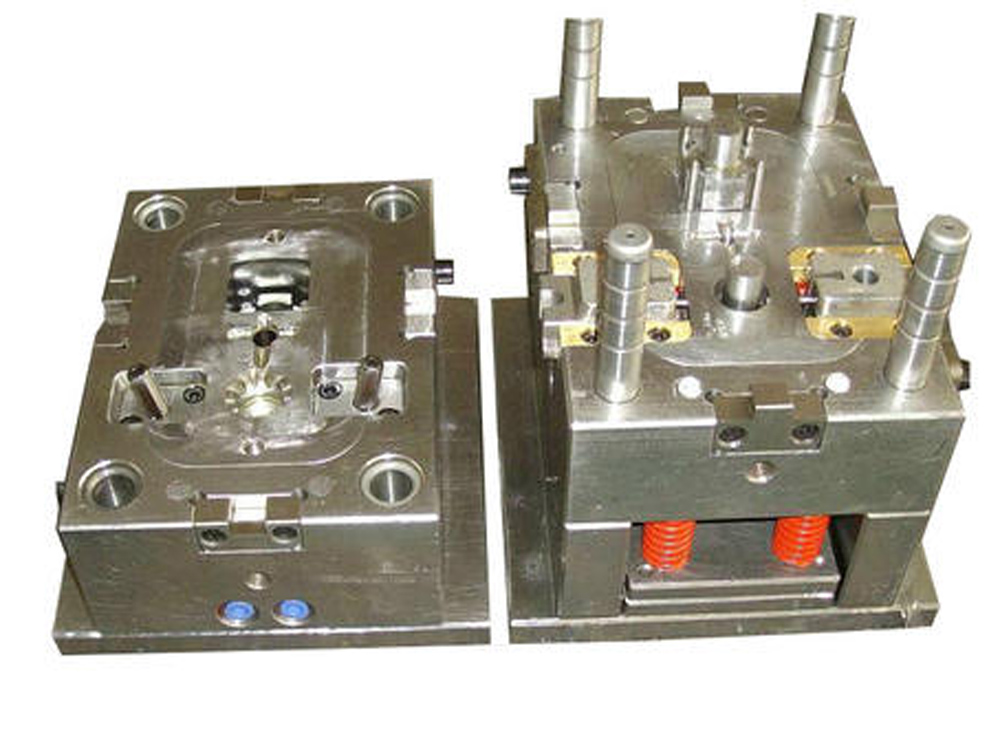

Product detail pictures:

Related Product Guide:

Cooperation

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for China OEM Semi Automatic Plastic Injection Moulding Machine Suppliers - Spraying paint for plastic products – Mestech, The product will supply to all over the world, such as: Canberra, Cyprus, Accra, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!