Plastic toilet seat mold

Short Description:

The plastic toilet seat mold is used to make toilet cover and related accessories. Plastic materials are light, fall resistant, moisture resistant and good skin touch feeling. They are used to replace ceramic and wood to make toilet covers and related parts.

Mestech company has many years of experience in making plastic toilet seat mold and injection molding, including common toilet seat / children's toilet seat / intelligent toilet cover.

Toilet is a common appliance in people's life. It can be found everywhere at home and in hotels. There are three kinds of materials for making toilet: Wood / ceramic / plastic. Plastic toilet is widely used at present because of its own advantages

Wood is not as resistant to moisture and corrosion as ceramics and plastics

The ceramic toilet is made of clay. The ceramic is relatively brittle. The wall must be very thick. The toilet made of it is bulky. Therefore, the freight is high and the installation is inconvenient

Toilet cover belongs to bathroom products, bathroom industry is a big classification of plastic injection molding industry. The main plastic parts in the toilet cover (toilet cover and toilet seat) are mainly processed by injection molding process.

Plastic material comes from petroleum. It is light and easy to form. It can be made into various shapes, sizes and colors. It is very suitable for efficient industrial production. At the same time, the moisture resistance and corrosion resistance of plastic is better than that of wood, with light weight and low price. Therefore, it has great advantages over wood and ceramic toilets

Material selection of toilet seat cover: The good plasticity of plastic, toilet seat can be made by injection molding a variety of shapes, color and surface patterns suitable for different groups of people and become popular in markets.

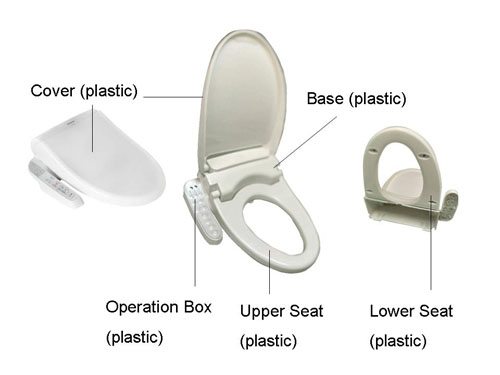

A toilet seat and mainly consists of below plastic parts

A. Cover: material PP, ABS

B. Upper seat: material PP,ABS

C. Lower seat: material PP,ABS

D. Operation box: ABS, ABS/PC

The plastic parts in a toilet seat

1).Mold for toilet seat plastic parts.

Mold is also necessary to make toilet cover. Toilet cover mold requires high gloss, so the mold core material requirements are good, but the product shape is simple, mold processing is easy.

2).The selection of injection molding machines

Mainly injection molding machines. The size of the toilet cover and seat is large, and the injection machine needed is more than 700 or 800 tons.

3). Material selection. There are four kinds of plastic materials for toilet covers. Urea formaldehyde resin, PP, ABS, PVC.

① PP. PP material is the first one to appear. Its advantages are cheap material and convenient processing. But its aging resistance is not good. It's very aging after 2 or 3 years. In addition, the material is soft and the scratch resistance is not good.

② Urea formaldehyde resin. Urea formaldehyde resin is very special in plastic. It does not belong to thermoplastic resin. It is a thermosetting resin. It is a polymer that urea reacts with formaldehyde. It has high strength, oil resistance and scratch resistance. But its disadvantages are inconvenient processing, high cost, poor toughness, brittleness, poor dyeability, and environmental protection, so ABS was introduced.

③ ABS resin. ABS is characterized by convenient processing, good environmental protection and moderate strength, but its scratch resistance is not as good as urea formaldehyde resin.

④ PVC resin. PVC resin in plastic material processing is not good, but the price is low, at the same time, good dyeing can transfer out a variety of patterns, low price is also a prominent feature of PVC toilet cover. The disadvantages of the toilet cover are soft, non environmental protection and poor scratch resistance.

Generally speaking, in the field of toilet cover, urea formaldehyde resin and ABS have good strength and are durable. They are good materials for toilet cover and seat. PP and PVC are soft and not scratch resistant

Mold for plastic toilet cover

The size of the toilet seat is large, so their injection mold size is larger than that of the general molds. Large injection molding machine is also needed for injection production.

As the toilet seat always touches the human's skin, in order to ensure the comfort and no harm to the skin, the toilet covers are generally made into a high gloss surface, without painting and other spraying coating. The material of their molds should be steel which is easy to polish. The gates and runners of the molds should be designed to avoid defects such as welding line, streak , shrinkage and deformation.

Mold for plastic toilet cover

Toilet design technology changes with each passing day. For the intelligent toilet seat, there are wires connected with inductors, electronic components and control circuits, so as to detect the status at any time and realize the automatic service functions. The intelligent toilet brings people a comfortable feeling. The structure and design of the toilet become more and more sophisticated and complex.

If you have plastic toilet seat or cover need molds or injection molding, please contact us.