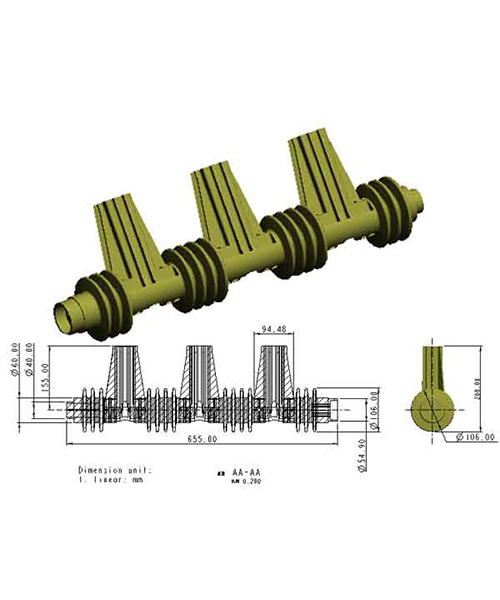

Nylon shaft for high voltage electrical switch

Short Description:

Nylon’s excellent electrical and mechanical properties are often used to make parts of equipment working under high voltage and high temperature, such as nylon shaft for high voltage electrical switch, container box, bearing, etc.

Nylon has good mechanical properties, high and low temperature toughness, impact resistance, wear resistance, self-lubrication, flame retardant, insulation and other characteristics. It is widely used in automotive, mechanical, electronic, instrumentation, chemical and other fields, such as gears, pulleys, bearings, impellers, bushings, containers, brushes, zippers and so on.

Nylon parts have high strength and toughness in high and low temperature environment, as well as excellent electrical insulation performance, so they are widely used in high-voltage electrical equipment to replace metal parts such as iron and steel.

Following is a case study of nylon spindles and joints for injection moulding of high voltage equipment for our customers.

Product name: Switch Shaft of High Voltage Control Cabinet

Mold standard (Customized) DME HASCO MISUMI China

Mold type: 2 Plate, mass production mold

Lead Time: 45-50workdays

Mold life: 300000-500000 Shots

Mold base: LKM

Mold cores' Material: S136H, H13

Cavity: 1*1

Hardness: HRC50-52

Runner system: Cold runner system

Gate type: Open system

Sample submission time: within 3days after test shot

Injection machine: 650 tons

Injection production: China

Transport of goods: Sea/air

Design Software: UG,Proeng

This switch shaft is used in a arc extinguishing device of High Voltage Control Cabinet.

It is required to have enough rigidity, toughness and good electrical insulation in high and low temperature environment, so we choose nylon PA66 70G33L to make it.

Nylon has good fluidity. In order to ensure no burrs, sharp edge,bubble, deformation to create,we machined the insert of the core and cavity of the mold with high precision and fit carefully the cavity and core inserts of injection mold, and design right runner and gate.

The size of the part is large, and it requires enough strength and good injection structure, and the weight should be as small as possible, so the structure design is complicated.

Nylon is a kind of plastic which is corrosive to the mould. We use the material of the mould to use corrosion-resistant steel.

The tips of Injection molding process on the nylon shaft:

Including barrel temperature, injection pressure, injection speed and mold temperature

(1) . barrel temperature: the part material is PA66, and the drying temperature is 85-100 ° C, which takes 3-6 hours. The temperature of injection molding barrel is 275 ~ 280 ℃. Due to the poor thermal stability of nylon, it is not suitable to stay in the barrel for a long time at high temperature, so as not to cause material discoloration and yellowing.

(2) . injection pressure: because the parts with complex shape and thin wall thickness are prone to defects, higher injection pressure is still needed, which is set within the range of 200-250mpa

(3) Injection speed: injection nylon benefits from high speed

(4) . mold temperature: the wall thickness of the part, taking into account the dimensional stability of the part, and the mold temperature takes the middle range. 60~80 degrees C

Mestech company is engaged in the production of injection moulds and injection moulds for nylon parts of high voltage electrical equipment. Please contact us for more information or quotation.