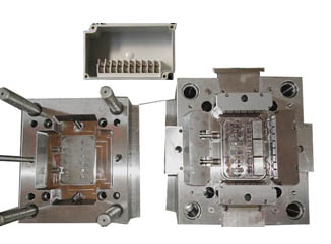

Aluminum Mold Making - China Manufacturers, Suppliers, Factory

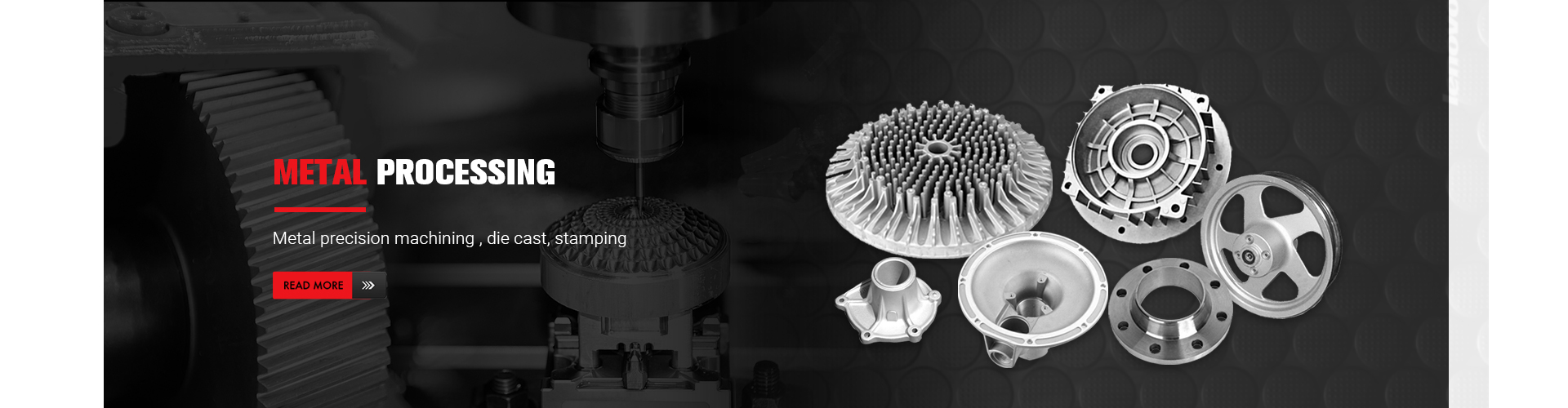

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for Aluminum Mold Making, Tunnel Gate Inserts, Machined Parts, Plastic Parts For Automotive Industry,Stackable Plastic Storage Box Injection Molding. We have expanded our business into Germany, Turkey, Canada, U. S. A. , Indonesia, India, Nigeria, Brazil and some other regions of the world. We are working hard to be one of the best global suppliers. The product will supply to all over the world, such as Europe, America, Australia,Somalia, Cape Town,belarus, Seychelles.Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers' satisfaction is our future!

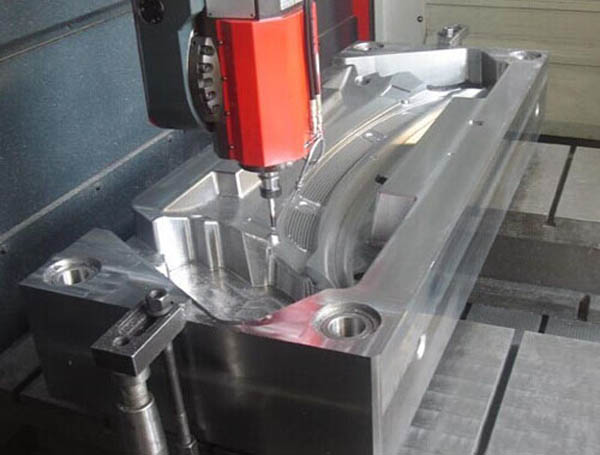

Related Products