Automobile bumper and injection molding

Short Description:

The bumper is located at the front and rear of the car. The bumper of a car is normally made of plastic injection molding.

Automobile bumper is a structure which absorbs and reduces external impact and protects the front and rear ends of an automobile. Many years ago, the front and rear bumpers of automobiles were stamped into channel steel with steel plates, riveted or welded together with the longitudinal beams of the frame, and had a large gap with the body, which looked very ugly. With the development of automobile industry and the extensive application of engineering plastics in automobile industry, automobile bumper, as an important safety device, is also on the way to innovation. Today's front and rear bumpers of cars not only maintain the original protection function, but also pursue harmony and unity with body shape, and pursue their own lightweight. The front and rear bumpers of cars are made of plastic. People call them plastic bumpers.

Front plastic bumper for automobile

Rear plastic bumper for car

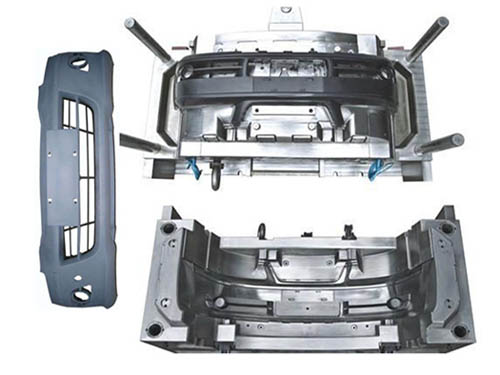

Plastic bumper and injection mold

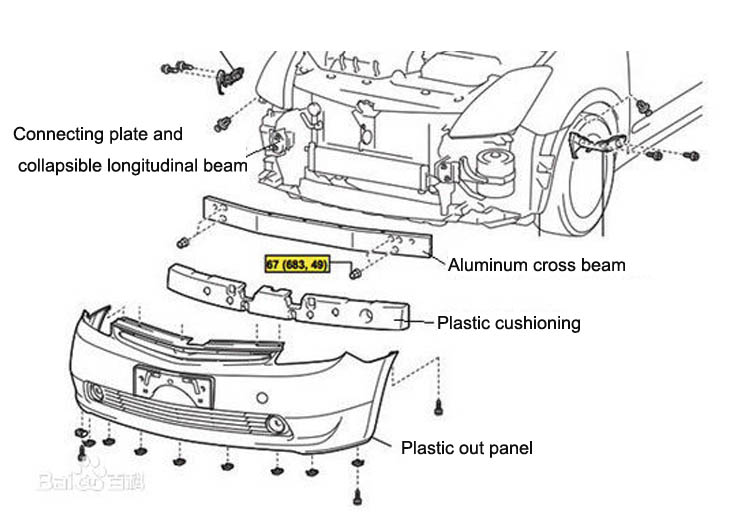

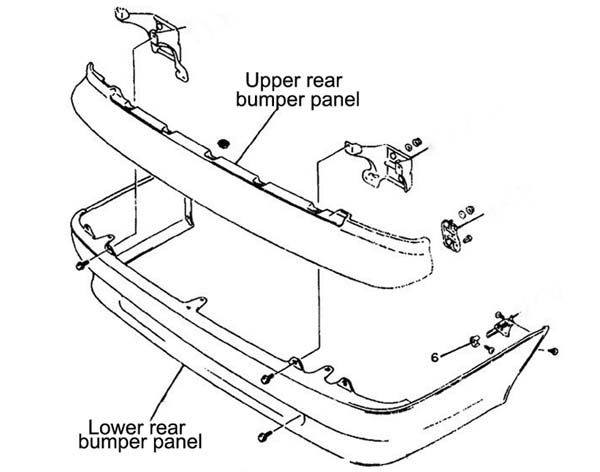

Composition of automobile bumper

The plastic bumper of general automobiles is composed of three parts: outer panel, cushioning material and cross beam. The outer panel and cushioning material are made of plastic, and the cross beam is stamped with cold rolled sheet to form U-shaped grooves; the outer plate and cushioning material are attached to the cross beam.

The Composition of automobile front bumper

The Composition of automobile rear bumper

The feature of the injection mold for automobile bumper

For automobile bumper plastic parts, there are two types of parting: external parting and internal parting. For all large area buckles on both sides of automobile bumpers, either external or internal type can be used. The choice of these two parting methods mainly depends on the requirement of bumper for the final customer automobile main engine factory. Generally, European and American automobiles mostly adopt internal parting technology, while Japanese automobiles mostly adopt external parting.

The two types of parting have their own advantages and disadvantages. External parting bumpers need to deal with parting lines and increase processing procedures, but the cost and technical difficulty of externally parting bumpers are lower than that of internal parting bumpers. The inner-parting bumper can be perfectly injected into the bumper by means of secondary rail-changing control technology, which ensures the appearance quality of the bumper and saves the processing process and cost of the plastic parts. But the disadvantage is that the cost of the mold is high and the technical requirement of the mold is high, because of its high quality appearance, it is widely used in middle and high-grade automobiles.

Material of automobile bumper

Nowadays, the automobile bumper is mostly made of PP modified material by injection moulding instead of metal.

Because the size of bumper is very large, the length of bumper is usually more than 1 meter, and the size of injection mould is often more than 2 meters. Large machine tools are needed to make injection moulds, which take a long time to make. Large injection moulding machines with a capacity of more than 1500 tons are also used for parts production, which is not a small investment.

Mestech provides customers with plastic mold making and injection production of auto parts. If you need to make bumper injection mold or injection production, please contact us.