Double-shot backlit keycaps

Short Description:

Double-shot backlit keycaps ( Double-injection backlit keycaps) are made through the double-injection molding process. This process can produce high quality keycaps in dimensions and surface. Two material combine together very firmly, and can be any color assortment.

Backlight keycaps allow light to pass through the transparent area of the button surface, prompting the operator, to see the keys clearly in dark or dark environments or by flashing lights. The double shot backlit keycaps of two material has the best effect and the most widely used.

Keyboard with backlit keycaps

What is the advantage of double-shot backlit keycaps

Backlight keyboard is mainly reflected in the keyboard keys or panel light, you can clearly see the key letters in the dim or dark environment .

Each key of the keyboard uses a special plastic black part with good shading, white part with a strong transparency, so as to achieve the basic function of the backlight keyboard. It is quite convenient for people to deal with affairs at night, and the appearance of keyboard is very beautiful.

Backlight keyboards differ from other keyboards: The main difference between backlight keyboards and other keyboards is that the backlight keyboard is backlit at night, so that it can be operated well at night. The general keyboard does not emit light. It is difficult to see clearly at night. Then the backlight keyboard uses white light-emitting diodes, but the general keyboard is not.

Transparent keycap is one of the most important parts of keyboard luminous module.

About transparent backlit keycaps

The types of keys can be divided into plastic keys and silica gel keys.

According to the requirements of transmittance, key cap can be divided into three types:

A. impervious;

B. overall transmittance;

C. local pattern font transmittance, which is the most important and practical type of transmittance keys at present.

There are two technologies to make the backlit keycaps of pattern font in the market:

1. Laser engraving of transparent keycaps

1) The characteristics of laser engraving keycap: transparent main body, surface spraying, radium engraving font, font luminous, main shortcomings, spraying, surface paint will wear;

Mainly using laser principle to process the surface keys, many key manufacturers will use radium carving process to produce key products, often used on mobile phones, electronic dictionaries, remote controllers, keyboard products, keyboard lights on the keys, the use of "optical couplet" radium carving process keys will make the key products more beautiful and natural.

2). Manufacturing technology of keycaps for laser engraving font:

Laser-engraved fonts on keyboard surface reveal deep substances through evaporation of surface substances, or cause chemical and physical changes of surface substances to produce traces by light energy, or burn some substances by light energy, and "engrave" the traces, or burn some substances by light energy, showing the required etched graphics and text. Laser engraving font on keyboard surface is suitable for silica gel keys and hard plastic keys (transparent plastic PMMA, PC, ABS). The common process is that the keyboard base is transparent material, and dark opaque paint is sprayed on the surface. Then it is put on the laser engraving machine. The opaque paint on the surface is burned at high temperature along the font path to expose the opaque base of the font area.

Laser engraving fonts on the keyboard surface do not require a specific mold, and can be made in any number.

2. Double-shot molding backlit keycaps

1). Characteristic of double-shot injection moulding key cap: the main body of the key cap is opaque, the font is transparent, the font is luminous, and the font is abrasive. Main drawbacks: Surface fonts are easy to spill glue during injection moulding.

2). Manufacturing process of double-shot injection-moulded light-emitting key cap:

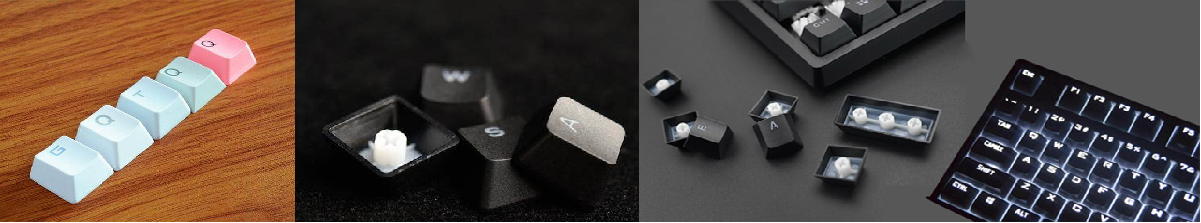

Backlight key caps are usually made of two-color materials by double injection moulding. The base part is made of opaque black plastic material, and the transparent font part is made of transparent plastic (PC, PBT), which is injected into a whole through the mould twice, thus realizing the basic function of transparent keyboard font.

Because of the high price of the double-shot mould, this manufacturing method is only suitable for the light transmission keys of products with large orders. For example, games, computer keyboards and other large number of high-grade products.

*Introduce two types popular double-shot injection molding keycaps----PBT backlit keycaps , P+R backlit keycaps

PBT backlit keycaps

PBT keycap is one type of double shot injection moulding key cap, in which the material of transparent font part is plastic PBT.

The process of double shot backlit keycaps

Backlight keycaps are usually made of two materials by double-shot injection molding. The cap body is common opaque plastic ABS or ABS/PC which has a good shading, and the white part in the center is plastic material PBT and has a strong transparency, thus realizing the basic function of the backlight keyboard. It is quite convenient for people to deal with affairs at night, and the appearance of keyboard is very beautiful.

The application of PBT keycaps

PBT keycaps are high hardness, wear resistance and no need to paint. PBT keys are very popular for gamers' keyboards. PBT keycaps are mostly white. With the maturity of the process, PBT keys on the market now have a variety of colors, a variety of monotonous colors and even rainbow colors have been used by merchants.

PBT backlit keycaps and keyboards

P+R double injection backlit keycaps

It is to use two-color injection molding to make a key cap with backlight effect. Take the hard transparent plastic (ABS or PC) as the main body, and cover the soft opaque plastic (TPR, TPU or TPE). Backlight through the soft glue left out of the text, soft surface fingers feel good contact. The characters and patterns on the top of keys are directly formed by injection molding. The process is simple, the productivity is high, and the cost is low. It is suitable for mass production of products, such as keyboards, medical instruments, educational products and toys.

Mestech company specializes in the injection mold and production of double injection molding backlight keycaps. If you need to make backlight key, please contact us.