China OEM Electric Injection Molding Machine Manufacturers - How to make auto dashboards – Mestech

Short Description:

China OEM Electric Injection Molding Machine Manufacturers - How to make auto dashboards – Mestech Detail:

Plastic auto dashboard is an important interior in an automobile.

The auto dashboards generally made of plastic resin “modified PP” or “ABS/PC”. The automobile dashboard (also called dash, instrument panel , or fascia) is a control panel usually located directly ahead of a vehicle’s driver, displaying instrumentation and controls for the vehicle’s operation. An array of controls (e.g., the steering wheel) and instrumentations are installed onto the dashboard to show speed, fuel level and oil pressure, the modern dashboard may accommodate a broad array of gauges, and controls as well as information, climate control and entertainment systems. So it is designed and made in complex structure to fit and locate those controls and instrumentations firmly and undertake their weight.

Automobile dashboard system

For different dashboards, the processes involved are also quite different, which can be roughly summarized as follows:

1. Hard plastic dashboard: injection moulding (parts such as dashboard body) welding (main parts, if necessary) assembly (related parts) .

2. Semi-rigid foam dashboard: injection/pressing (dashboard skeleton), suction (skin and skeleton) cutting (hole and edge) assembly (related parts).

3. vacuum molding / plastic lined (skin) foaming (foam layer) cutting (edge, hole, etc.) welding (main parts, if required) assembly (related parts) .

Materials for each part of dashboard

| Part name | Material | Thickness (mm) | Unit weight (gram) |

| instrument panel | 17Kg | ||

| Upper body of instrument panel | PP+EPDM-T20 | 2.5 | 2507 |

| Airbag frame | TPO | 2.5 | 423 |

| Instrument panel lower body | PP+EPDM-T20 | 2.5 | 2729 |

| Auxiliary instrument panel body | PP+EPDM-T20 | 2.5 | 1516 |

| Trim panel 01 | PP+EPDM-T20 | 2.5 | 3648 |

| Trim panel 02 | PP-T20 | 2.5 | 1475 |

| Decorative panel 01 | PC+ABS | 2.5 | 841 |

| Decorative panel 02 | ABS | 2.5 | 465 |

| Air duct | HDPE | 1.2 | 1495 |

| Moving ashtray | PA6-GF30 | 2.5 | 153 |

The main processes for making auto dashboards are as follows:

Injection molding process: the drying plastic particles in the injection molding machine through screw shear and barrel heating and melting after injection into the mold cooling process. It is the most widely used processing technology in the manufacture of dashboards. It is used to manufacture the body of hard-plastic dashboards, the skeleton of plastic-absorbing and soft dashboards and most other related parts. Hard plastic dashboard materials mostly use PP. The main materials of dashboard skeleton are PC/ABS, PP, SMA, PPO (PPE) and other modified materials. Other parts choose ABS, PVC, PC, PA and other materials besides the above materials according to their different functions, structures and appearances.

If you need to make plastic parts or molds for the dashboard, or if you need more information。Please contact us.

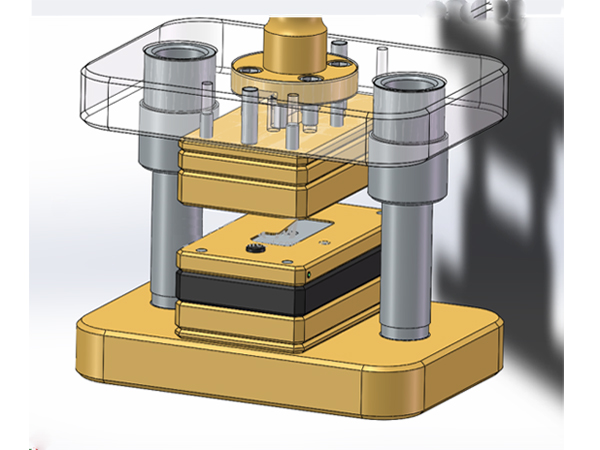

Product detail pictures:

Related Product Guide:

Cooperation

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for China OEM Electric Injection Molding Machine Manufacturers - How to make auto dashboards – Mestech, The product will supply to all over the world, such as: Karachi, Japan, Los Angeles, We are introduced as a one of the growing manufacture supplier and export of our products. We have a team of dedicated trained professional who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.