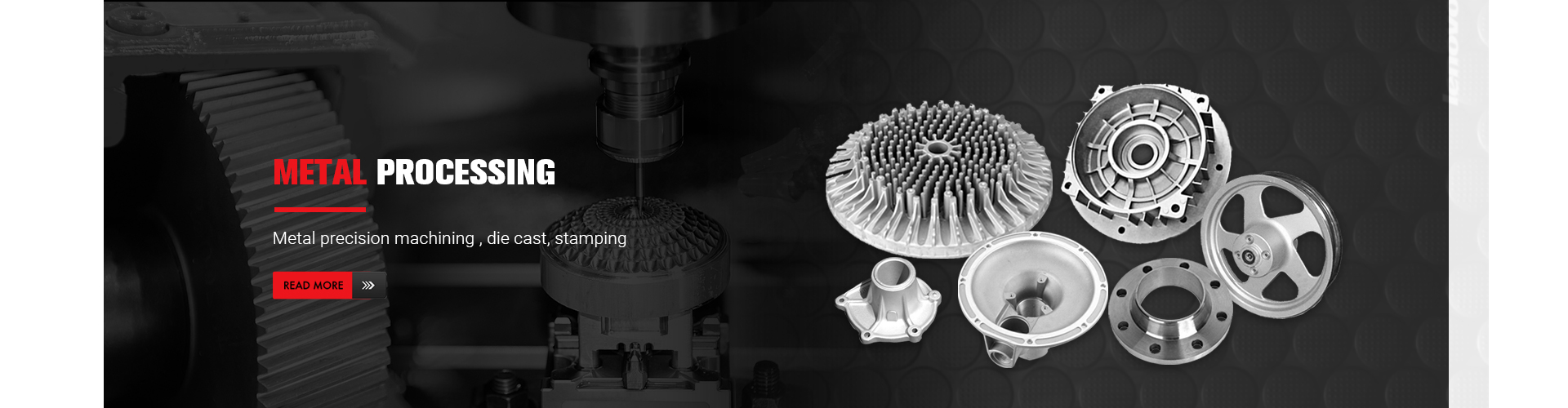

Gas Injection Moulding - China Manufacturers, Suppliers, Factory

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for Gas Injection Moulding, Zinc Alloy Parts Design, Small Batch Cnc Machining, Steel Components Design,Automotive Plastic Injection Moulding. Any interest, make sure you really feel free to get hold of us. We're searching forward to forming prosperous enterprise interactions with new purchasers across the earth within the near upcoming. The product will supply to all over the world, such as Europe, America, Australia,Turkey, Comoros,Colombia, Luxembourg.We're introduced as a one of the growing manufacture supplier and export of our merchandise. Now we have a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

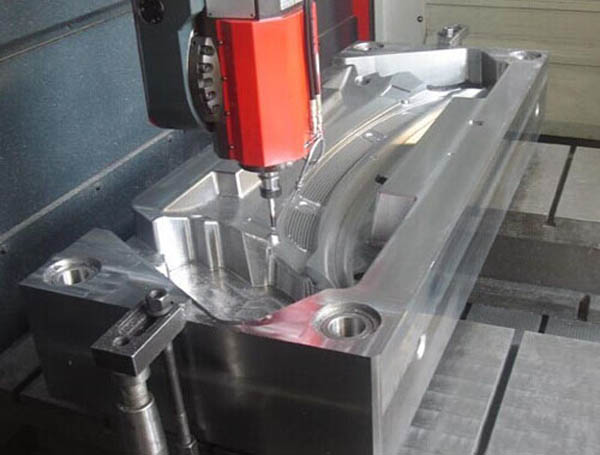

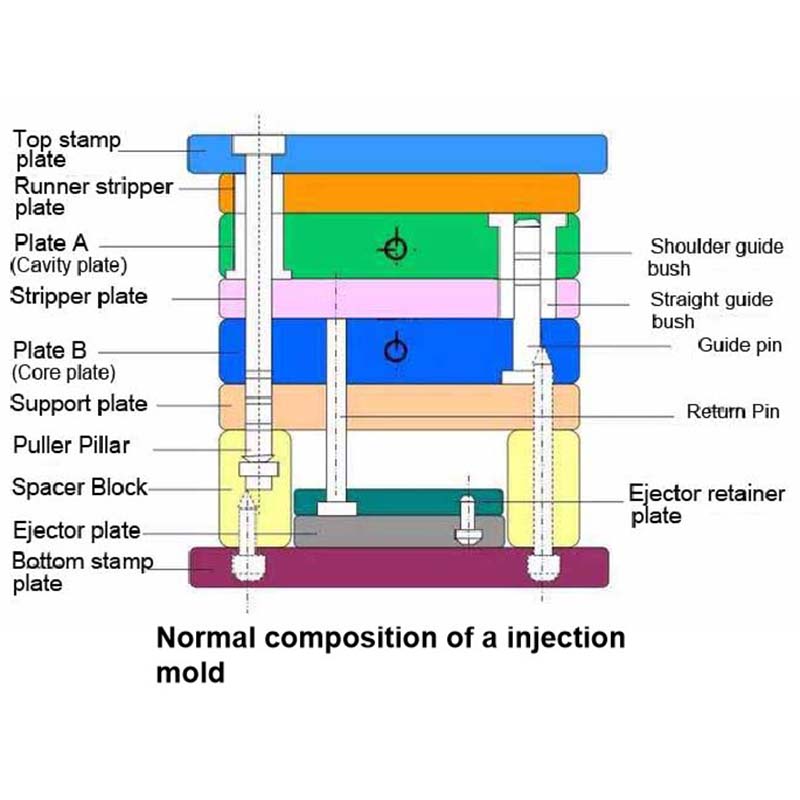

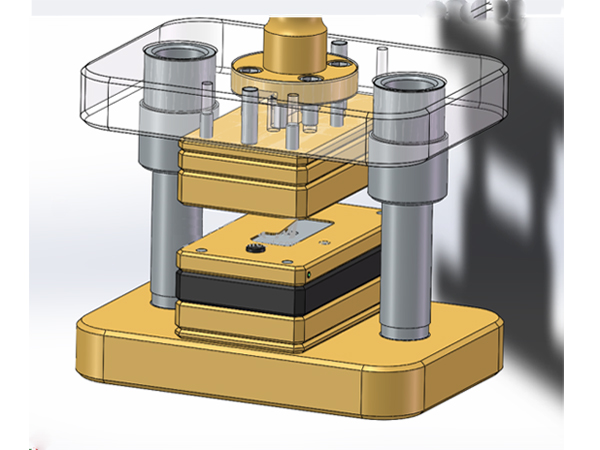

Related Products