China OEM Making Cement Molds Manufacturers - Insert molding – Mestech

Short Description:

China OEM Making Cement Molds Manufacturers - Insert molding – Mestech Detail:

Insert molding is a plastic injection molding process where plastic is injected into a cavity and around an insert piece or pieces placed into the same cavity just prior to molding. The resulting product of this process is a single piece with the insert or inserts encapsulated by the plastic.

Insert molding is the molding method that the mold is used to inject resin into the prepared insert with different materials, and the melted material is combined with the insert to form an integrated product. Embedded parts are usually metal parts, but also cloth, paper, wire, plastic, glass, wood, wire ring, electrical parts.

The process features of Insert molding are as follows :

1. It is necessary to consider the combination and supplement of the resin’s easy formability, bending, metal’s rigidity, strength and heat resistance, so as to make the complex and exquisite metal plastic integrated product.

2. In particular, the combination of resin insulation and metal conductivity is used, and the formed products can meet the basic functions of electrical products.

3. The pre forming combination of multiple inserts makes the post engineering of product unit combination more reasonable.

4. Insert products are not limited to metal, but also cloth, paper, wire, plastic, glass, wood, coil, electrical parts, etc.

5. For the rigid molding products and the bending elastic molding products on the rubber sealing base plate, the complex operation of arranging the sealing rings can be avoided after the integrated products are made by injection molding on the substrate, which makes the automatic combination of the subsequent processes easier.

6. Because it is the joint of molten materials and metal inserts, the gap between metal inserts can be designed narrower and the molding reliability of composite products is higher than that of press in molding..

7. Select appropriate resin and molding conditions, that is, for products that are easy to be damaged (such as glass, coil, electrical parts, etc.), they can also be sealed and fixed by resin.

8. With the combination of vertical injection molding machine and manipulator, the whole set of inserts and so on, most of the insert molding projects can realize automatic production.

9. after the insert is formed, it can also be made into products with hollow grooves after the core hole removal treatment.

Tips on the part design and mould of insert molding

1. Material requirements for inserts: hardness, melting point, rigidity, shrinkage

2. Whether the shape and size of the insert are convenient for taking, placing and positioning. The design of the parts shall be convenient for installation and fixation in the mold to prevent the parts from deviation or looseness under the impact of the flowing resin.

3. Manufacturing accuracy and consistency of inserts

4. Select the appropriate mold structure, and the inserts can also be completely sealed into the resin.

5. The forming shrinkage of the metal insert is easy to be uneven. The limit test of the shape and size accuracy of the important parts should be done in advance.

6. During the injection process, the metal insert is easy to deform and shift, so the mold composition and the design of mold shape that is easy to maintain the metal insert should be fully considered. For products whose insert shape cannot be changed, prior test is indispensable.

7. Confirm whether the metal insert needs preheating or drying treatment. The purpose is to ensure the product quality and forming stability.

Typical applications:

Metal insert molding Metal insert molding is the most widely used insert molding process.

Metal insert molding is a kind of method to fix the metal insert in a proper position in the mold in advance, and then inject plastic for molding. After the mold is opened, the insert is wrapped in the product by cooling and solidifying plastic to get the product with inserts such as threaded ring and electrode.

It is required that the parts of embedded metal inserts should have proper structure and thickness, and the parts of fixed inserts in the mold can be quickly and reliably positioned to prevent plastic from flowing into the fixing holes. The inserts also need to be specially designed, such as knurling, grooving, twisting, etc. in the embedded parts to ensure their reliable fixation in the plastic interior

Customized metal insert molding parts:

Mestech is a specialized application of insert molding.. Please contact us to help you find the correct insert molding solution for your application.

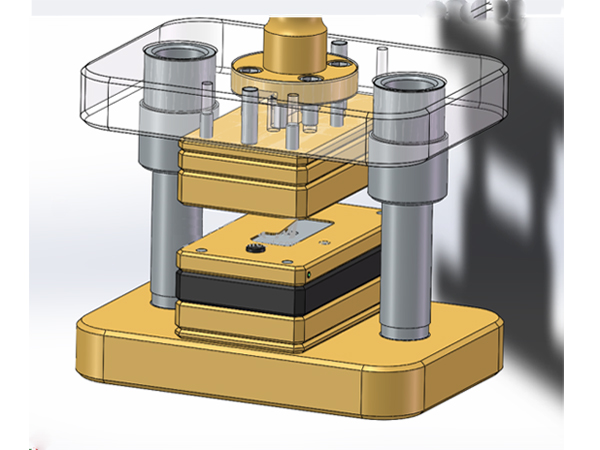

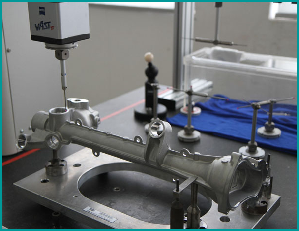

Product detail pictures:

Related Product Guide:

Cooperation

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of China OEM Making Cement Molds Manufacturers - Insert molding – Mestech, The product will supply to all over the world, such as: Denver, Rome, Bangladesh, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!