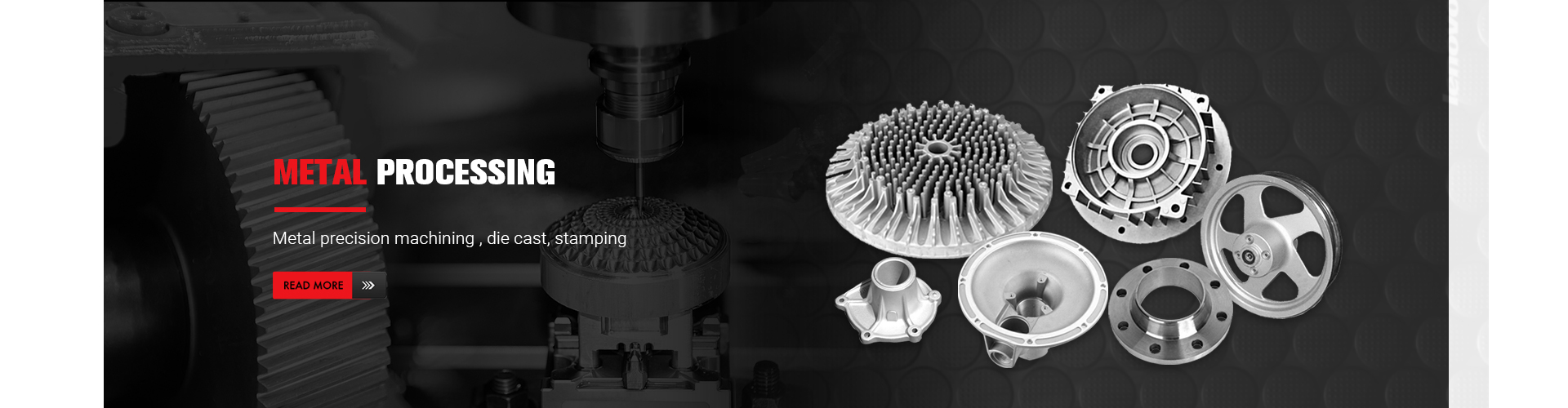

Insert Molding Process - Factory, Suppliers, Manufacturers from China

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for Insert Molding Process, Aluminum Parts Design, Vacuum Die Casting, Housing Design For Home Appliance,High Pressure Die Casting. Our tenet is clear all the time: to deliver high quality product at competitive price to customers around the world. We welcome potential buyers to contact us for OEM and ODM orders. The product will supply to all over the world, such as Europe, America, Australia,Sri Lanka, Nepal,Paraguay, Malaysia.We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We are willing to build long-term, friendly and mutually beneficial cooperation with you.

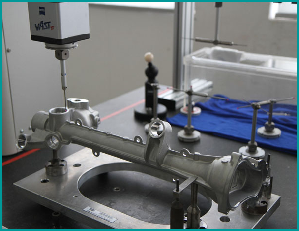

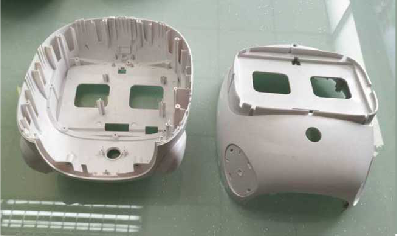

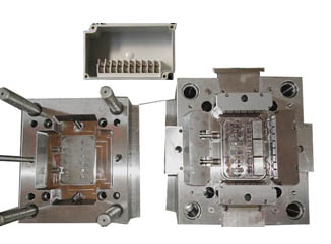

Related Products