Manufacture of plastic medical syringe

Short Description:

Plastic syringe assembly and injection molding

Plastic medical syringe is the most widely used syringe at present. With the good technological properties of plastic materials, we can produce them through large scale industrial production of injection moulding.

Let's share the plastic injection molding knowledge of plastic syringes.

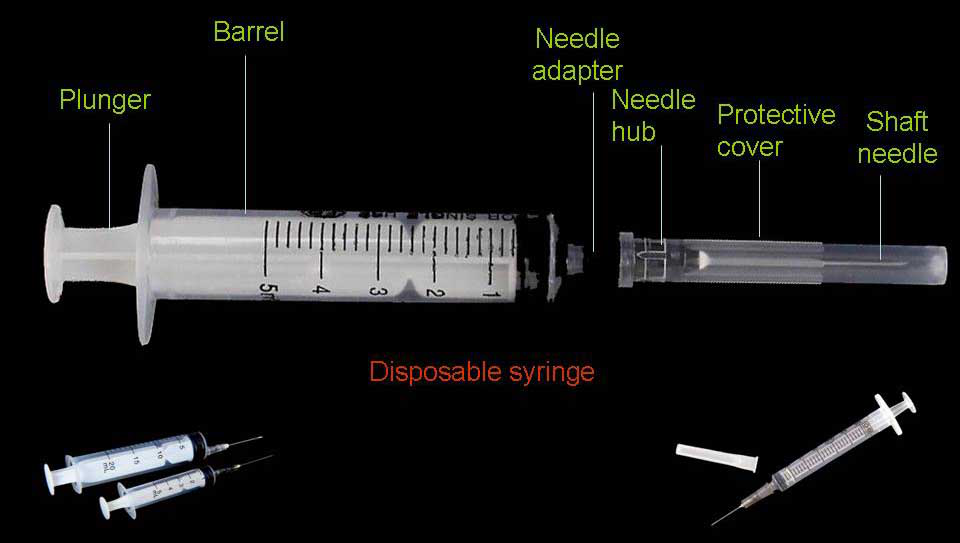

Components of plastic syringes

The syringe generally includes the following parts: needle, part label: plunger, cylinder, needle connector, needle hub, needle cone, needle shaft

Components of a plastic syringe

PP & polypropylene resin

Material of medical plastic syringe

Disposable syringe of plastic syringe generially are made of PP (polypropylene ) resin, which is medical grade.

Medical grade PP is certified by medical certification, such as meeting the requirements of USPClassVI and ISO10993, being listed in the FDA Drug Management File (DMF) and so on. It should conforms to:

1. Various sterilization options (high pressure, hot vapor, ethylene oxide, gamma ray, electron beam)

2. Excellent Transparency and Gloss

3. Superior Rigidity and Shock Resistance Balance with Minimum Distortion

4. Good impact resistance at low temperature

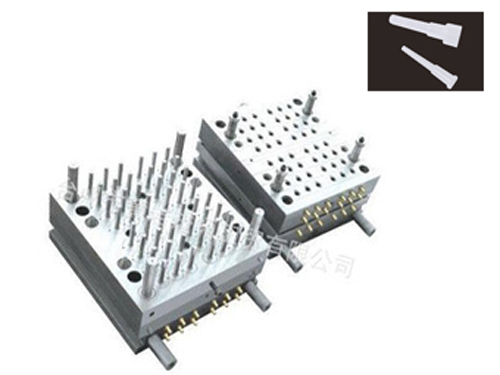

Mold and injection production for plastic syringe

For mass production of plastic syringes, the injection mold generally are made in multicavity. 4 cavity mold, 10 cavity mold,100 cavity mold or more cavity. It is decided by the orders of market.

The syringe injection production always run in a closed clean dust-free workshop, parts are taken and placed by manipulator during injection molding.

Mold for syringe barrels

Mold for syringe plungers

Mold for syringe protective covers

Mestech has excellent machinery and equipment and rich experience engineers. We are willing to provide you with injection moulding and injection moulding of syringes, if necessary, please contact us immediately.