Plastic parts for electronic

Short Description:

Plastic parts for electronic are widely used as housing and internal components of electronic products, which are a large category of plastic parts.

Due to the variety of electronic products, the corresponding plastic parts need to meet a variety of requirements, and the design structure, size and appearance are various. A wide range of plastic materials are used.

Electronic products cover a wide range, it has been deeply applied to all walks of life and our daily life. It mainly includes:

A. Computer and communication products --- mobile phone, computer, telephone, headset, smart watch;

B. Digital electronic products ---- audio, camera, DVD, power supply;

C. Office products --- printers, scanners, projectors, videophones, attendance machines;

D. Home electronics - doorbell, TV, smart door lock, electronic scale;

E. Medical care - sphygmomanometer, thermometer, monitor;

F automobile electronics and peripheral products --- automobile charger, emergency starting power supply, rear-view mirror;

G. Industrial Electronics - monitor, thermometer, hygrometer, pressure gauge.

H. Others such as electronic toys, environmental protection equipment, solar energy, sports fitness equipment, etc.

Laptop plastic housing

Plastic housing for printer and projector

Remote control housing

Plastic enclosure of automobile emergency power supply

Features of plastic parts used in electronic products:

1. Most sizes are medium or small, except for TV sets.

2. High dimensional accuracy: most electronic products are of exquisite structural design, compact coordination between parts, and accurate manufacturing dimensions of parts are required.

3. How many kinds are required: such as two-color material injection molding, mold decoration, etc.

4. High requirements for appearance quality: such as high gloss surface or post surface treatment, such as carving, painting, electroplating, water transfer, etc.

5. Most products are produced in large quantities, so the mold should have high production efficiency, repeated precision and service life.

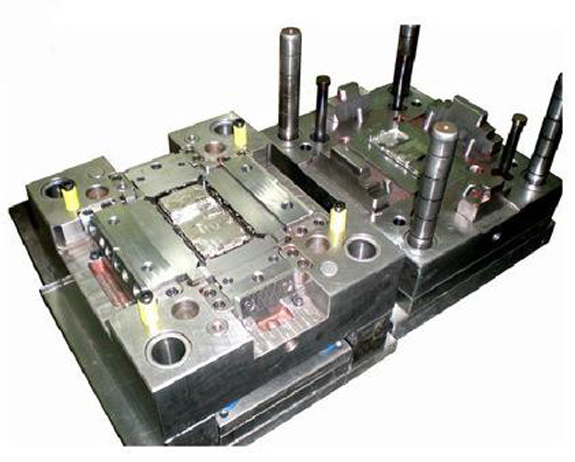

Injection mold for mobile phone

Tips of injection molding process for the plastic parts used in electronic products: 1. Mold making A. Select the right steel to make the mold: For high gloss surface and corrosive plastics, steel with high chromium content should be selected as the core, such as S136. For common surface parts, p20718 and other steels are generally selected as die cores. B. The position of the glue inlet should be selected reasonably, and the exhaust of the mould cavity should be reasonable and sufficient. C. For parts requiring post-treatment such as silk screen printing, electroplating or pressing copper nuts, the reserved clamping position shall be considered. D. Select the correct mold processing technology: for the parts with high size or surface requirements, the mold cavity should be finished, using high-precision CNC, slow wire cutting and mirror EDM to finish machining the cavity. 2. The precautions on electronic product plastic parts injection molding A. The barrel of injection molding machine shall be clean. Especially for appearance parts, there shall be no color mixing, speckles and materials. B. For high gloss parts or parts that need to be electroplated, there must be no scratch, and the surface shall be protected by film. C. For the parts with sealing requirements, the parts shall be free from deformation, and the sealing surface shall be clean without more or less glue on the edge. D. Parts working in high-pressure environment shall be free of edge, sharp angle, bubble and crack. E. For parts with large output, automatic production line of manipulator should be considered.

Electronic products are a large family, involving a wide range of processes. Our company provides long-term electronic products injection mold and parts molding and post-processing services. We are glad to provide you with professional services, please contact us.