Elastomer TPS wheel injection molding

Short Description:

TPS wheel is a kind of noiseless wheel. The injection molding of TPS elastomer wheel is representative.

As a thermoplastic elastomer, TPS and PU wheels have excellent tensile strength, high surface friction coefficient, good low temperature performance, excellent electrical performance, no rolling noise and adsorption vibration, etc. They are mainly used for casters of hospital trolleys, baby carriages, shopping trolleys and airport trolleys.

Mestech can provide various sizes and types of TPS and PU materials for casters and single wheel moulding and injection moulding.

Elastomer TPS wheel

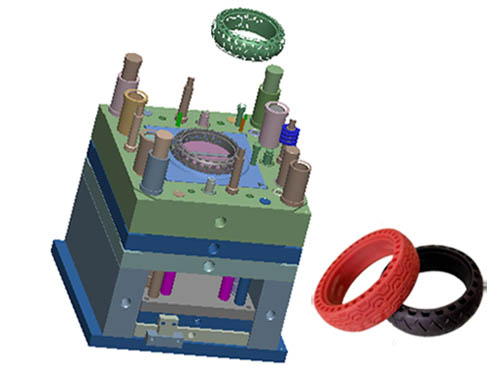

Mold and molding process of TPS wheel

1. There are radiation stripe pits around the wheel, so forced demoulding is adopted.

2. There are radiation distribution fringes around the wheel, so arc transition should be used between adjacent surfaces.

3. TPU/TPS materials with good fluidity are prone to batch edges in injection moulding, so the moulds cores should be well fitting.

4. The wheel is very thicker than usual and requires a bid power injection machine, and the injection time will be long.

Injection mold for TPS wheel

Tips of TPS wheel design

In order to increase the friction adhesion and better absorb vibration on the surface of the wheel, numerous holes and grooves with radial arrays centered on the hub axis are designed on the circumference of the plastic wheel. If the conventional die design is followed, the mold structure will be very complex or difficult to achieve, and the product will be difficult to withdraw. People have come up with a way: using elastic plastic TPS and PU as wheel coats, and putting them on the hub made of hard materials.

The elastomer TPS has the advantages of high friction coefficient, good wear resistance and good processing performance, good friction adhesion and vibration absorption, and good rigidity and strength depending on the hard central hub. At the same time, the elastic deformation characteristics of TPS and PU elastomers are used to forcibly pull out of the die cavity, thus avoid to make many complicated slider mechanism in the mold.

Our company is based in Guangdong, China. With good engineering experience and equipment, we provide themoplastic wheel design and production for your production, and ensure that the quality of products remains at a high level.